Prefabricated Tanks

Storage Tanks for Every Industry

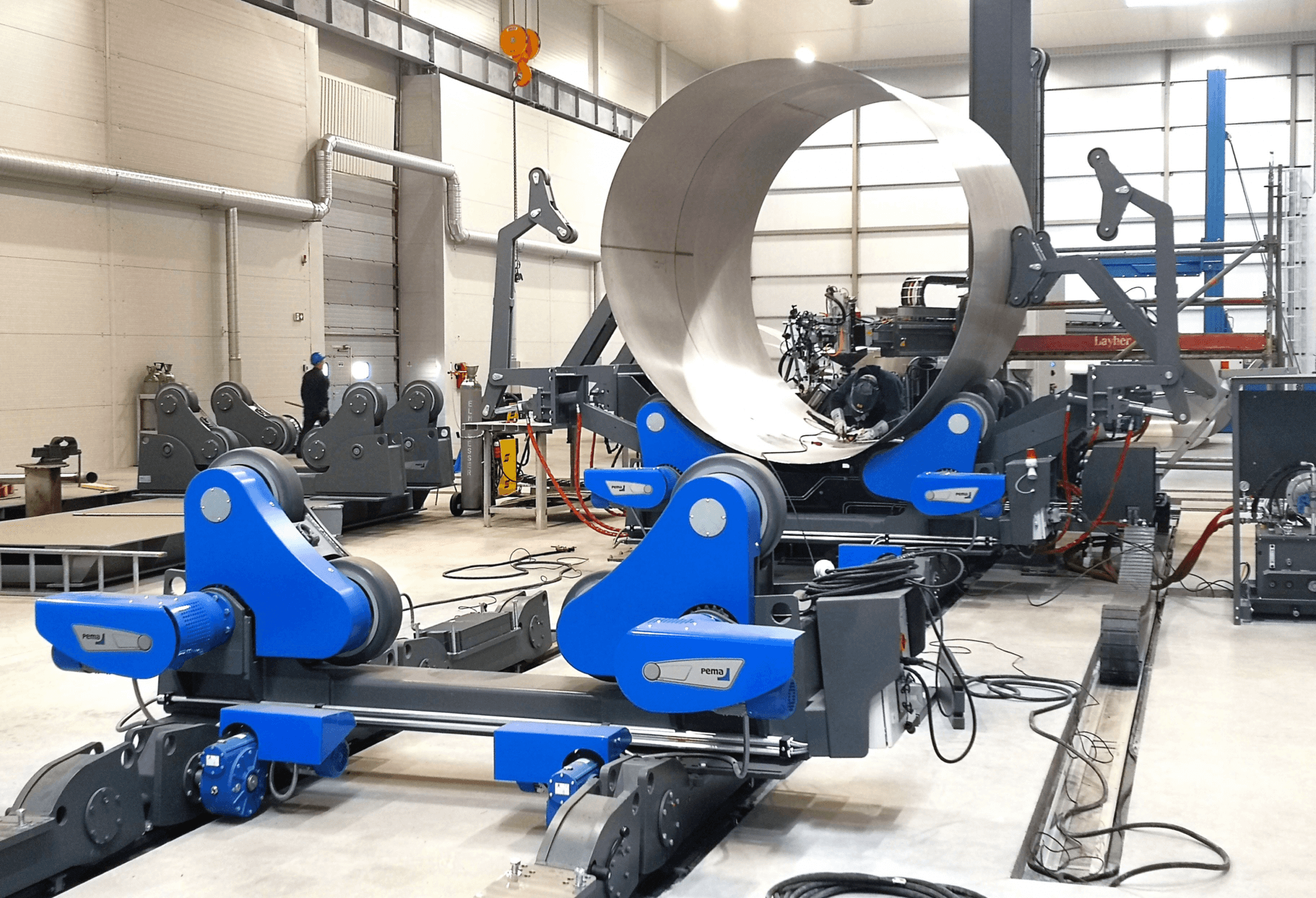

We design and manufacture durable and efficient storage and fuel tanks that serve a wide range of industrial applications. Stainless steel is the best material for manufacturing methanol storage and fuel tanks because of its high corrosion resistance, mechanical strength, and chemical inertness. Methanol is a harsh chemical that can degrade conventional metals, such as carbon steel. In contrast, stainless steel can effectively withstand the effects of methanol, ensuring durability, safety, and reliable storage. Built with precision and reliability in mind, our tanks are engineered to handle both everyday use and demanding operational conditions. From compact units to large-scale installations, every atmospheric or pressurized stainless tank we produce is tailored to meet specific client requirements.

Expertise Beyond Storage Tanks

While we are proud of our expertise in storage and fuel tanks, Western Technological Solutions also specializes in a wide range of industrial equipment. Our capabilities include the production of pressure vessels, scrubbers, CO2 capture and environmental equipment, as well as custom welding assemblies from stainless steel and aluminum. This comprehensive product offering allows us to support complex projects and provide integrated solutions that go far beyond standard tank manufacturing.

Quality and Reliability You Can Trust

Every tank we produce is manufactured under strict quality standards, ensuring compliance, durability, and long service life. We use advanced fabrication techniques and premium materials to create equipment that not only meets but exceeds customer expectations. Whether you need a mixing tank for production, a thermal storage tank for decarbonization or energy-saving projects, or a pressurized tank for demanding processes, our team delivers solutions you can rely on.

Our product range includes thermal energy storage (TES) tanks, mixing tanks, atmospheric and pressurized tanks, each crafted to deliver long-lasting performance and safety. A stainless steel tank offers excellent resistance to corrosion and hygienic properties, making it a preferred choice in the chemical, power, oil and gas, food, beverage, and pharmaceutical industries. For chemical processing and other demanding environments, our mixing tanks and pressurized tanks provide robust solutions that guarantee operational reliability.

To address the growing challenges of decarbonization and district heating, Western Technological Solutions has developed and launched a new line of Thermal Energy Storage (TES) tanks. These tanks play a critical role in helping the EU achieve its industrial decarbonization goals.

The most beneficial use of cold-water storage tanks is supplying chilled water for air conditioning and cooling systems (HVAC) in large commercial buildings, shopping malls, industrial facilities, data centers, hospitals, food processing facilities, and other environments where reliable temperature control is essential, with minimal operational expenses for cold generation.

Hot water storage tanks are commonly used in residential and commercial buildings, such as hotels, hospitals, recreation centers, greenhouses, and various industrial facilities. They provide a cost-effective, steady, and reliable source of hot water for various needs, including washing, cleaning, heating, and other processes.

Decarbonisation projects based on heat pumps or electric boilers can only be cost-effective when using thermal energy storage tanks.

The TES tanks offered by Western Technological Solutions are factory-built, available in pressurized and atmospheric models. They are vertical, cylindrical, above-ground, heat-insulated, stainless steel welded tanks, with flat bottoms and conical roofs, and can hold capacities of up to 500 m³. They are delivered as turnkey solutions at the customer’s site.

Our proprietary product line features TES with working volumes of 50, 80, 100, 150, 200, 300, 350, 400, and 500 m³, designed for a temperature of +95 °C.

Pressurized TES tanks are supplied with all relevant safety valves and measurement devices and are ready for integration into the Customer’s heat network.

The thermal insulation of the tank’s bottom, walls, and roof meets the highest energy efficiency Class A according to EN 17956:2024.

Materials to choose from: 1.4162 (duplex), 1.4062 (duplex), 1.4301 (AISI 304), 1.4404 (AISI 316L).

Design norms: PED 2014/68/EU, EN 13445.

Our TES tanks have an optimal height-to-diameter ratio to ensure natural stratification energy storage and are equipped with sophisticated, appropriate internals.

Factory-built stainless steel thermal energy storage tanks provide significant advantages for cost-effectively implementing decarbonization projects and ensuring long-term operational efficiency.

Exceptional advantages of our TES tanks:

- Lowest total operating costs throughout the tank’s lifespan due to no overhaul costs (unlike carbon steel tanks).

- Extremely safe (unlike carbon steel).

- Maintaining high asset value throughout the tank’s lifespan due to corrosion resistance (unlike carbon steel).

- Super Long durability (unlike carbon steel).

- Saving on the duration of engineering, design work, and construction.

- Insensitive to heat carrier quality (unlike carbon steel)

- Superior Class A insulation delivers exceptional thermal efficiency with minimal losses.

- Smallest footprint.

- Mobility and possibility of relocating.

- Stainless Steel is the most eco-friendly metal.

Customers will receive a ready-to-use, pre-designed thermal energy storage (TES) tank.

The key difference between TES tanks of the same volume for different projects lies in the various orientations of the nozzles, tailored to meet the specific requirements set by the customer.

Once the TES tank order is confirmed, we will provide a 3D model, a P&ID diagram, concrete foundation requirements, and datasheets for the included mounted devices. These documents will facilitate the seamless integration of the ordered TES tank into the overall design of the customer’s project.

Our installation team will carry out a turnkey installation of the TES tank at the customer’s site. This includes the installation of advanced thermal insulation, fastening the tank, fitting the protective cover, mounting safety valves and measuring devices, and conducting commissioning tests.

Let’s decarbonize the EU together!

Partner with Western Technological Solutions

By choosing Western Technological Solutions, you gain a reliable partner committed to engineering excellence. From storage and fuel tanks to complete process equipment, we combine technical expertise with customer-focused service to help your business operate smoothly and efficiently.

Technological Expertise

Advanced stainless steel and aluminum solutions for industrial precision.

Comprehensive Capabilities

Full-cycle production from engineering to delivery in one hands.

Experienced Team

Skilled professionals backed by Western Shipyard Group and

BLRT Group.

Quality Assurance

Certified to ISO 9001,

EN 1090 EXC3, and

ISO 3834-2 for proven excellence.

Client-Oriented Approach

We adapt to every client’s unique needs for optimal project results.

International Presence

Part of BLRT Group, serving clients across the Baltic and global markets.