Stainless Steel & Aluminum Structures

Stainless Steel and Aluminum Assemblies

Strong, reliable, and versatile welding assemblies are essential for modern industries and infrastructure. At Western Technological Solutions, we design and manufacture high-quality stainless steel and aluminum welding assemblies that combine durability with precision engineering. From large-scale frameworks to customized solutions, our expertise ensures every project meets the highest standards.

Expertise Across Industries

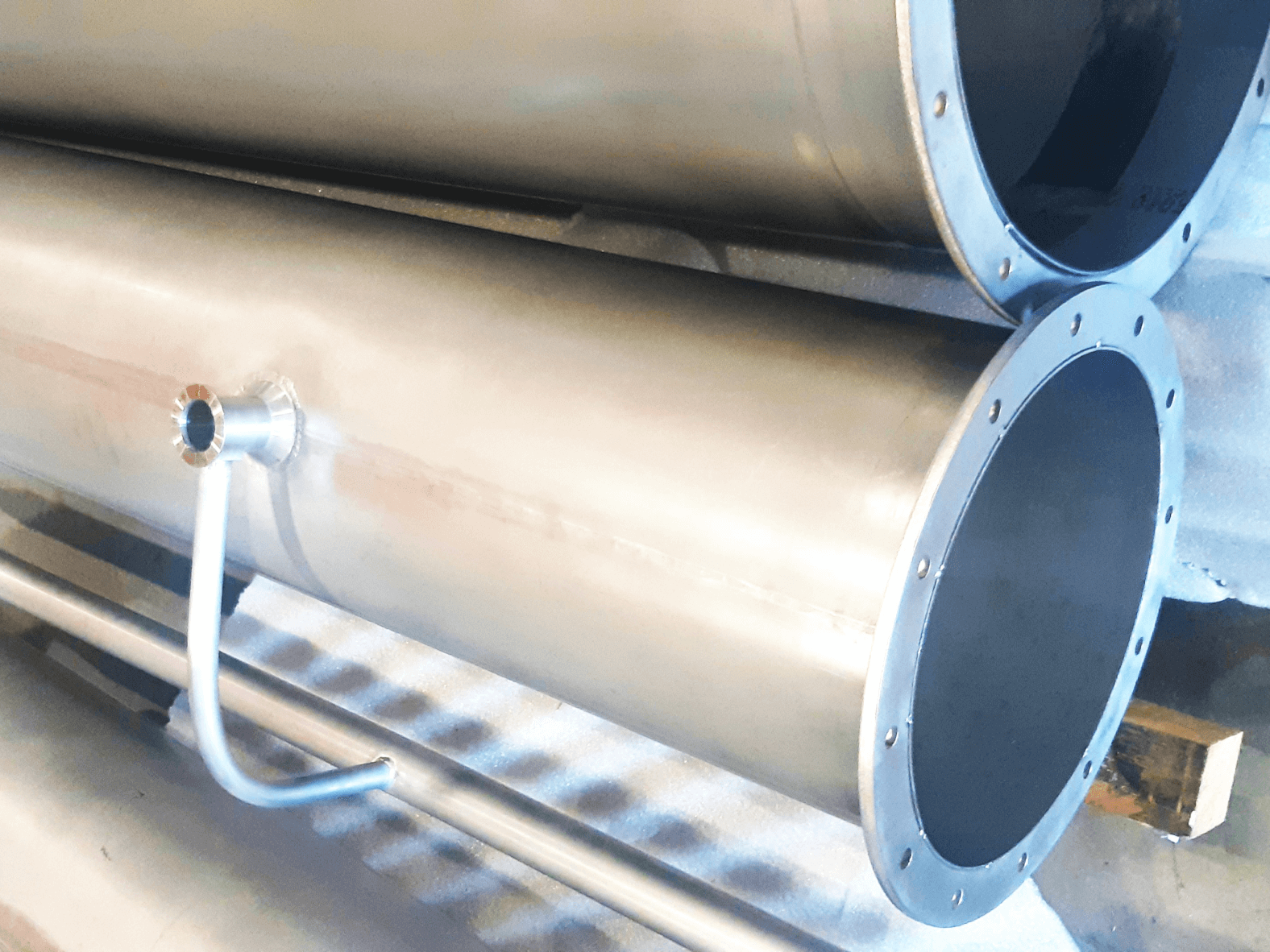

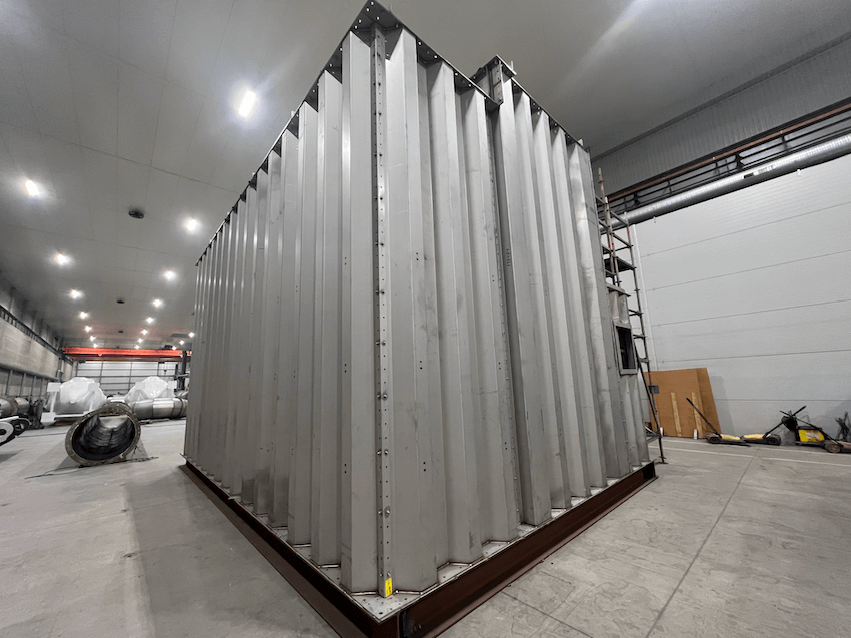

While stainless steel and aluminum structures are a key focus, Western Technological Solutions also specializes in manufacturing pressure vessels, storage and fuel tanks, scrubbers (exhaust gas scrubbers), and CO₂ capture and environmental equipment. This broad expertise allows us to provide complete, integrated solutions that support industries ranging from construction and infrastructure to energy, marine, and chemical processing.

Built on Quality and Innovation

Every project we deliver is supported by strict quality standards, innovative engineering, and a commitment to long-term performance. Whether it’s a stainless steel bridge, a duplex bridge, or complex welded assemblies, our team ensures that every structure is built to last and tailored to meet customer needs.

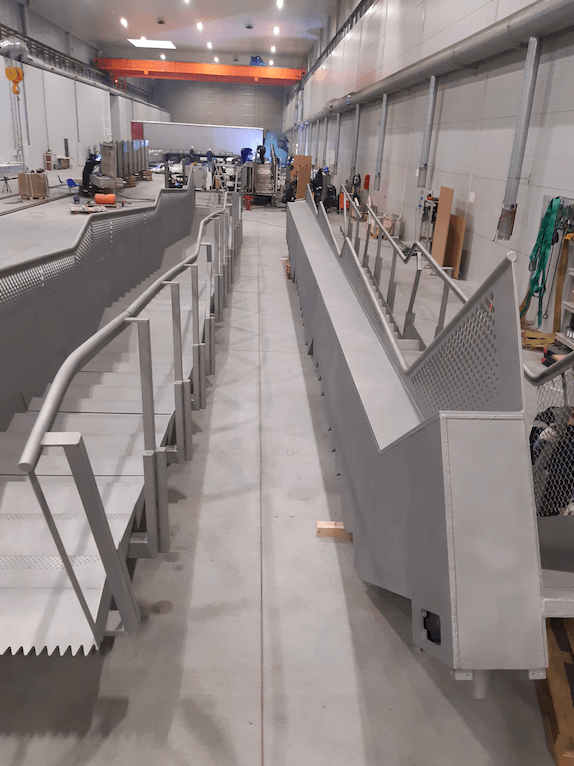

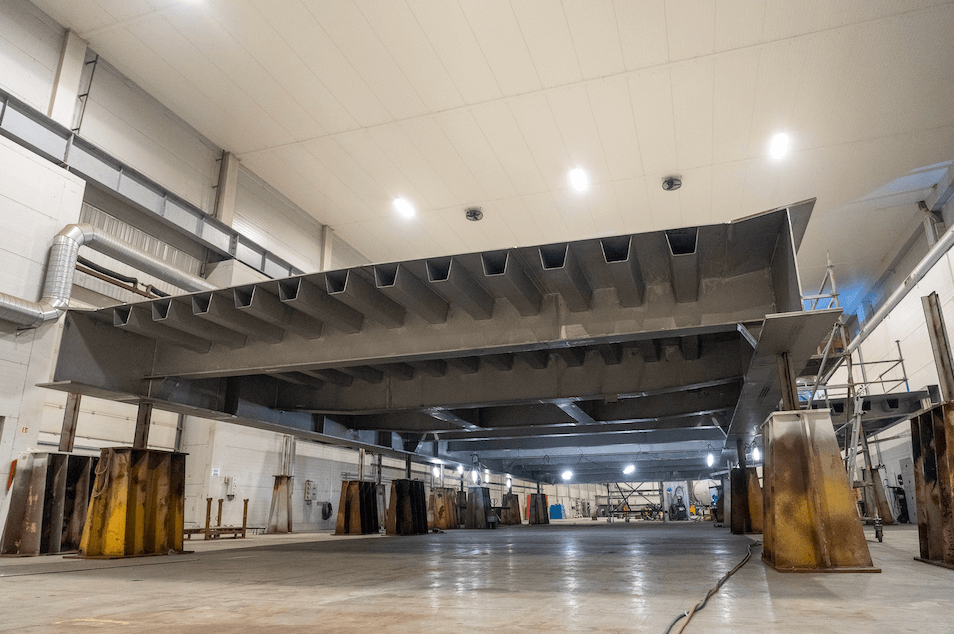

Our portfolio includes specialized products such as stainless steel bridges and duplex bridges, both of which are designed for exceptional strength, corrosion resistance, and long service life. These structures are built to withstand heavy loads, harsh climates, and long-life continuous use, making them a reliable choice for infrastructure projects. A stainless steel or duplex pedestrian bridge is ideal for environments where durability and low maintenance are crucial. Stainless steel and duplex bridges are a truly smart choice for investing in long-life infrastructure. Comparing only capital expenditures (CAPEX) is insufficient for funding long-term infrastructure objects. Over the lifespan of the stainless/duplex bridge, total capital and operational expenditures (OPEX) will be lower compared to a bridge made of carbon steel, providing long-term economic and maintenance benefits. Applying Total Cost of Ownership (TCO) is essential when evaluating long-term investments like bridge construction, as it provides a comprehensive view of all costs associated with the project – not just the initial purchase or construction expenses. TCO helps decision-makers choose materials and designs that offer the best value over time. This approach ensures more sustainable and cost-effective infrastructure planning, especially when comparing options like stainless steel versus carbon steel.

Precision in Welded Assemblies

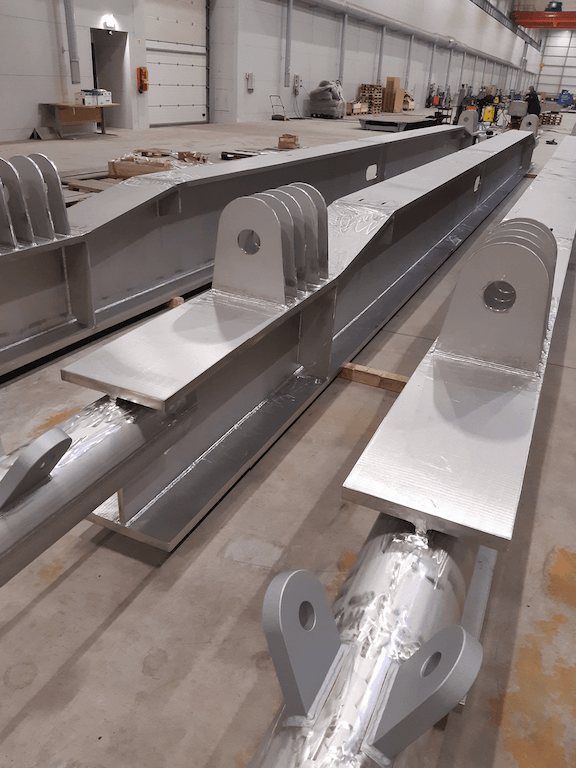

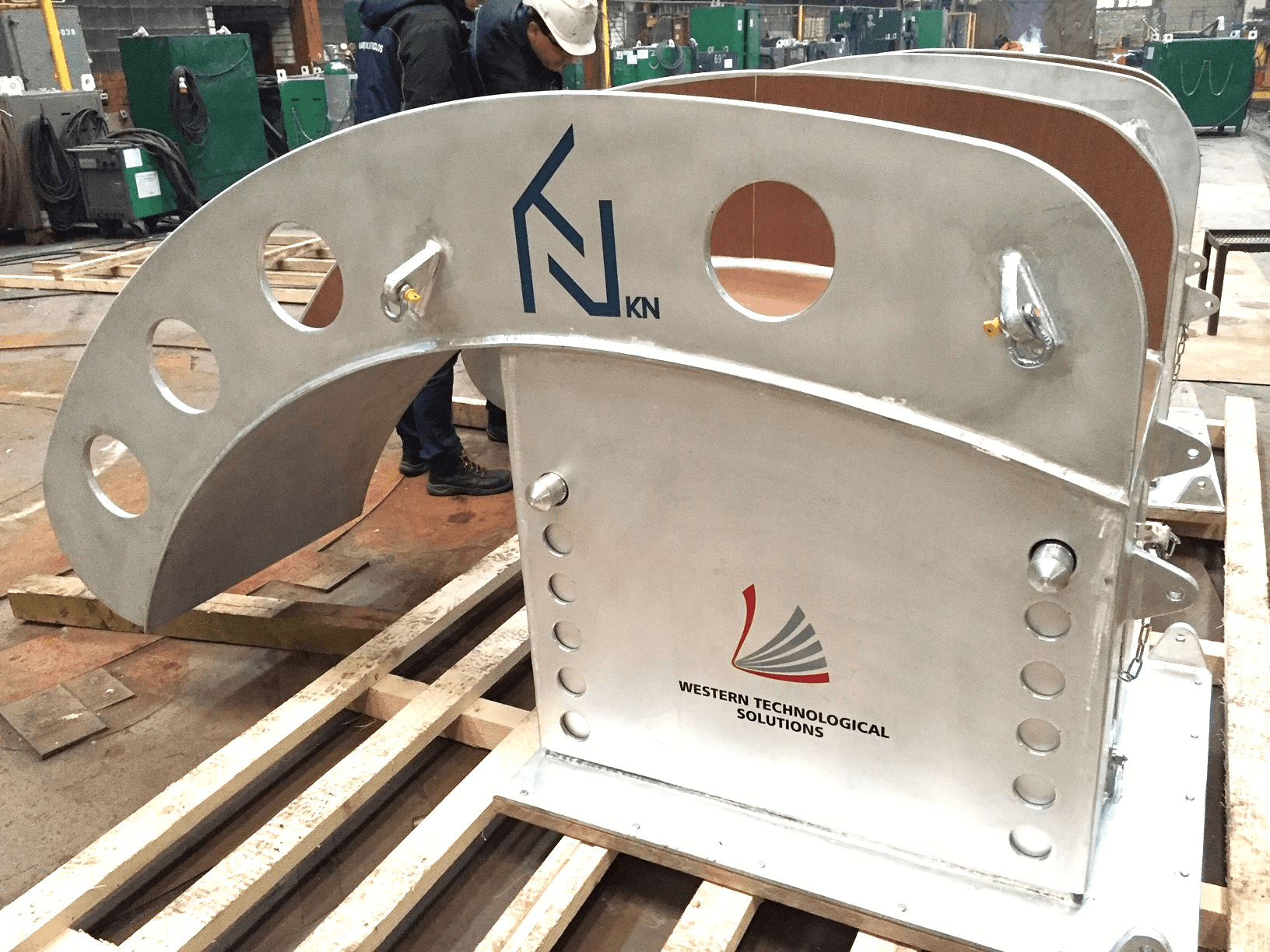

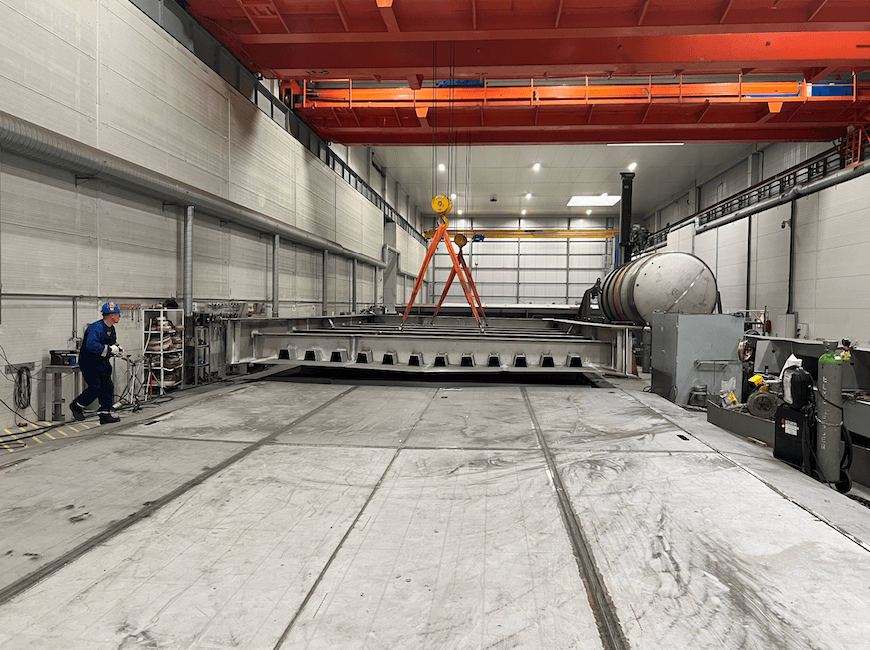

In addition to bridges, we produce various welded assemblies that are tailored to client specifications. Using advanced welding techniques and premium materials, our assemblies deliver strength, precision, and adaptability for a wide variety of industrial applications. Each assembly is carefully manufactured to ensure seamless integration with larger systems, offering both reliability and efficiency. Dimensional accuracy of large-scale assemblies can be reliably ensured using advanced laser scanning systems, which provide precise, real-time measurements and comprehensive geometry verification.

Technological Expertise

Advanced stainless steel and aluminum solutions for industrial precision.

Comprehensive Capabilities

Full-cycle production from engineering to delivery under one roof.

Experienced Team

Skilled professionals backed by Western Shipyard Group and

BLRT Group.

Quality Assurance

Certified to ISO 9001,

EN 1090 EXC3, and

ISO 3834-2 for proven excellence.

Client-Oriented Approach

We adapt to every client’s unique needs for optimal project results.

International Presence

Part of BLRT Group, serving clients across the Baltic and global markets.