Infrastructure and Capabilities for Stainless Steel Manufacturing on the Baltic Sea

Western Technological Solutions possesses advanced industrial manufacturing capabilities for large and heavy stainless steel projects, leveraging the extensive infrastructure of Western Shipyard and BLRT Grupp. Our facilities include an engineering office, a clean workshop, a pickling and passivation chamber, a laser, hydroabrasive, and plasma cutting facilities, rolling and welding equipment, a painting chamber, certified laboratory testing, open assembly areas on the sea piers, direct access to a sea pier, sea delivery, and logistics support for customers across the European and global market.Our unique advantage is our ability to produce and deliver large, one-piece stainless steel or combined stainless steel and carbon steel products by sea, with weights reaching hundreds of tons.

Our facilities, infrastructure and capabilities:

Engineering services

- 3D CAD modelling

- CAE simulations

- Strength calculation

- Structural analysis

- 2D workshop drawings

- BOM (Bill of Materials)

- Cutting cards and routing

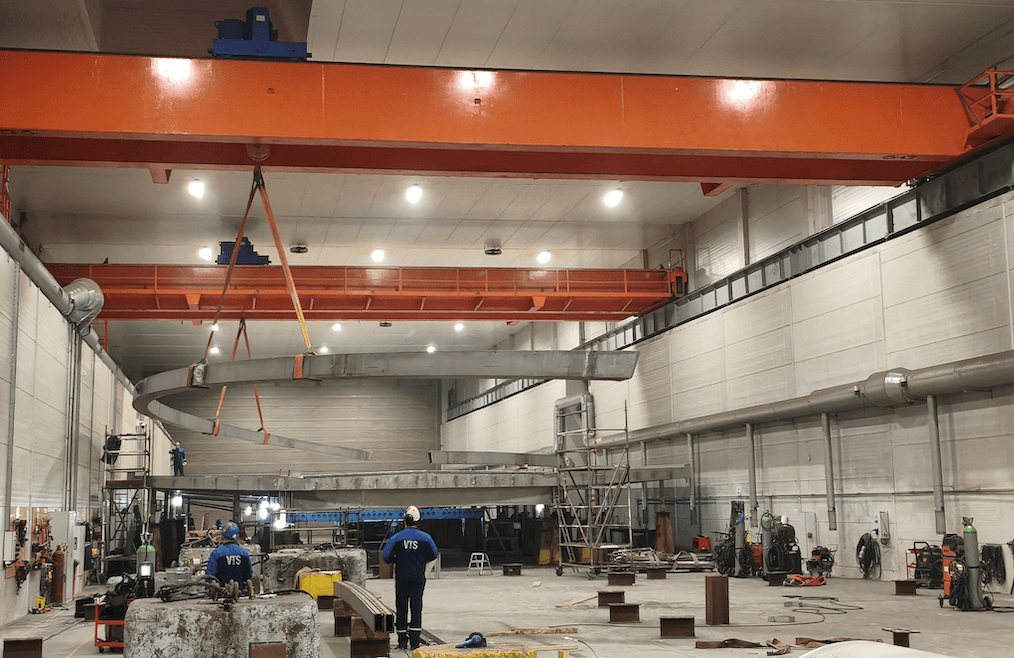

Clean Workshop for Stainless Steel

- Working area: 3240 m²

- Length: 162 m

- Width: 20 m

- Height: 8.5 m

- Gate Size: 20 × 8 m (W x H)

- Indoor Rail-Mounted Gantry Cranes: 2 units × 30 t capacity

- Climate Control: Temperature regulation and air recuperation systems

Western Technological Solutions operates a state-of-the-art stainless steel clean workshop, specifically engineered to meet the highest international quality standards. Our facility is equipped with advanced machinery designed for the specialized fabrication of large tanks, pressure vessels, and complex welded assemblies.

Our controlled production environment is a critical asset. By strictly separating stainless steel operations, we eliminate cross-contamination from carbon steel and other pollutants. This ensures exceptional surface quality and material integrity throughout every stage of production:

- Precision Cutting

- High-Spec Welding

- Structural Assembly

- Advanced Finishing

The clean workshop is outfitted with specialized stainless steel tooling and operates under certified processes and strict quality control procedures.

We support mission-critical projects for high-demand sectors, including:

- Carbon Capture and Storage (CCS)

- Renewable Energy & Power Generation

- Chemical & Petrochemical

- Food & Beverage

- Large-Scale Infrastructure

- Oil & Gas

- Decarbonization

By maintaining rigorous cleanliness standards and precise manufacturing practices, Western Technological Solutions delivers durable, corrosion-resistant stainless steel solutions that remain fully compliant with international regulations and bespoke customer specifications.

Main Fabrication Equipment

Rolling equipment

FACCIN 4HEP-S60 Heavy-duty 4-roll plate bending machine:

- Max width: 3150 mm

- Max rolling diameter for shells: 6000 mm

- Max thickness: 22 mm

- Rolling from 3 mm thickness

- CNC controlled (SIEMENS)

- 4-roll synchronized bending rolls with planetary guides for superior rigidity and precision

Rolling operations are fully programmable and CNC-controlled using the latest SIEMENS PGS ULTRA control system, ensuring high precision, repeatability, and efficient production cycles for demanding plate-rolling applications.

The plate roll is equipped with specially designed hydraulic top, front, and back supports, enabling reliable rolling of thin materials down to 3 mm thickness into large-diameter shells. These supports maintain the plate’s shape throughout the rolling process, effectively preventing plate buckling under its own weight and eliminating the need for cranes or additional external handling equipment.

The hydraulic back support also features integrated, hydraulically operated aligning arms, allowing precise edge alignment and tack welding while the workpiece remains in position. This significantly reduces setup time and ensures accurate seam preparation before the rolled component is removed from the machine.

Sawing equipment

IMET BS 350 GH Autocut Band Sawing Machine

High-performance double-column band saw designed for automatic and semi-automatic cutting of metal profiles and solid materials. Engineered in Italy, this robust band saw delivers exceptional cutting accuracy, reliability, and productivity, making it an ideal solution for metal fabrication workshops, steel service centers, and industrial production lines.

This band sawing machine is suitable for cutting:

- Structural stainless steel profiles

- Solid bars and tubes

- Stainless steel and alloy steel

- Aluminum and non-ferrous metals

With adjustable cutting angles and smooth blade guidance, the BS 350 GH Autocut adapts easily to straight and angled cuts, supporting a wide variety of industrial applications.

Automatic welding equipment:

Heavy-duty column and boom welding manipulator for hard automation welding PEMA HDS 6,5×5 with PEMA TW 6000-50S assembly line.

Key Specifications:

- 135, 136, 121 welding processes.

- Cylinders assembling Ø1500 – 6000 mm

- Weight up to 50 t

- Length up to 50 m

- PEMA welding column & boom WM 6,5 x 5 HDS is equipped with both MIG/MAG and SAW welding heads along with position sensors for mechanical seam tracking.

- Two premium quality XVC-S SAW and XCV-1000e MIG/MAG cameras with laser guide and crosshair functions allow for constant visual control of the welding seams by the operator the operation monitors.

Manual welding equipment:

- PEMA AP 3500 three-axis welding positioner for heavy-duty welding applications, enabling precise manipulation of large and complex workpieces. Designed to bring joints into the optimal welding position, this positioner significantly improves weld quality, productivity, and operator ergonomics. Adjustable height, tilt, and rotation for optimal welding position

- Fastmig X5 450 MIG Welder.

Modular, multi-process industrial welding system.

Processes: MIG/MAG, Pulse MIG, DC TIG, MMA, Gouging.

- Kemppi MasterTig 325 DC Water Cooled.

High-performance TIG welding power source.

DC TIG and MMA (stick) welding processes.

Water jet cutting system

Key Technical Specifications:

- Cutting thickness: 3 – 200 mm

- Operating area: 3000 × 8000 mm

- Cutterheads: 2 (straight cutting)

- High-pressure pump: KMT, 5200 bar

- Cutting standard: ISO 9013

- Tolerances:

ISO 9013 – 231 for materials 3 – 40 mm

ISO 9013 – 241 for materials 40 – 50 mm

ISO 9013 – 2*1 for materials 50 – 200 mm

High-precision industrial cutting solution designed for accurate, efficient, and flexible processing of a wide range of materials. Using ultra-high-pressure water jet technology, this system ensures cold cutting without thermal deformation, making it ideal for demanding industrial applications.

This advanced water jet cutting machine delivers exceptional cutting accuracy across both thin and thick materials. With a powerful KMT high-pressure pump operating at 5200 bar, the system guarantees consistent performance, smooth cut edges, and minimal material waste.

The machine supports stainless steel thicknesses from 3 mm up to 200 mm, making it suitable for a wide variety of production needs – from delicate components to heavy-duty industrial parts.

The generous 3000 × 8000 mm working area enables cutting of large stainless steel sheets and complex geometries with high precision.

These tolerances guarantee dimensionally accurate parts, smooth edges, and consistent quality throughout the entire cutting range.

Advantages of Water Jet Cutting:

- No heat-affected zone (cold cutting technology)

- Suitable for stainless steel

- High edge quality with minimal finishing required

- Environmentally friendly and material-efficient

- Ideal for both prototype and serial production

Laser cutting system

Key Technical Specifications:

- Technology: Fiber laser cutting

- Laser power: 6000 W / 10000 W

- Plates processing areas: 2

- Operating area: 2500 × 8000 mm and 2550 × 6250 mm

- Cutting thickness range: 0.5 – 25 mm / 0.5 – 30 mm

Designed for continuous industrial use, the laser cutting system combines rigid machine construction with intelligent CNC control. This ensures stable cutting performance, high repeatability, and long-term reliability in demanding production environments.

Benefits of Laser Cutting Technology:

- High cutting speed and precision

- Smooth cut edges with minimal finishing required

- High energy efficiency compared to traditional cutting methods

- Suitable for mass production and custom parts

- Reduced material waste and operating costs

Laser cutting is the most widely used cutting method for stainless steel sheets, especially for thin materials, as it delivers high cutting speeds, excellent edge quality, minimal heat-affected zone, and precise dimensional accuracy.

Plasma cutting system

Key Technical Specifications:

- Plasma system: Hypertherm HPR400XD

- Technology: High-Definition Plasma Cutting

- Cutting thickness range: 3 – 50 mm

- Operating area: 3500 × 22,000 mm

- Cutting Tolerances: ISO 9013 – 432

Advantages of High-Definition Plasma Cutting:

- High cutting speed for medium and thick materials

- Excellent cost-to-performance ratio

- Lower operating costs compared to laser cutting for thick plates

- Reliable performance in harsh industrial conditions

- Suitable for continuous production environments

With an extended working area of 3500 × 22,000 mm, the Hypertherm HPR400XD system is ideal for stainless steel large plates, long parts, and heavy structural components. This large operating area allows efficient processing of oversized materials while maintaining high accuracy.

Laboratory Testing & Quality Control

Western Technological Solutions and the Western Central Laboratory (wcl.lt) are subsidiaries of the Western Shipyard Group.

The Western Central Laboratory is a state-of-the-art facility specializing in welding process control and comprehensive testing. Their expertise covers both destructive and non-destructive methods to ensure the highest quality in stainless steel welded assemblies, structural components, tanks, pressure vessels, and custom-engineered products.

The control of welding processes is coordinated by internationally recognized welding engineers (IWE) and welding inspectors (IWI) who are certified according to ISO 14731 requirements.

The laboratory has all the necessary certifications and qualified personnel to provide non-destructive testing (NDT) services for our products.

Number of Certified NDT Inspectors:

- NDT acc. ISO 9712 with Level II > 12

- NDT acc. SNT-TC-1A with Level II > 10

Typical NDT Testing Performed on Our Products:

- Visual Testing (VT)

- Ultrasonic Testing (UT)

- Magnetic Particle Testing (MT)

- Penetrant Testing (PT)

- Radiographic Testing (RT)

- Leak Testing (LT)

Offered Mechanical testing:

- Tensile, Bend, Flattening, Stretching Tests

- Impact Resistance Tests

- Hardness Tests

- Welded Samples Testing

- Microstructure And Macrostructure Analysis

- Determination of the Chemical Composition of Metals and Metal Alloys

- Other Mechanical Tests

Chemical laboratory analysis:

- Determination of concentration of salts on metal surfaces.

- Determination of dustiness of metal surfaces.

- Material Identification

- Air pollution.

- Water.

- Petroleum products.

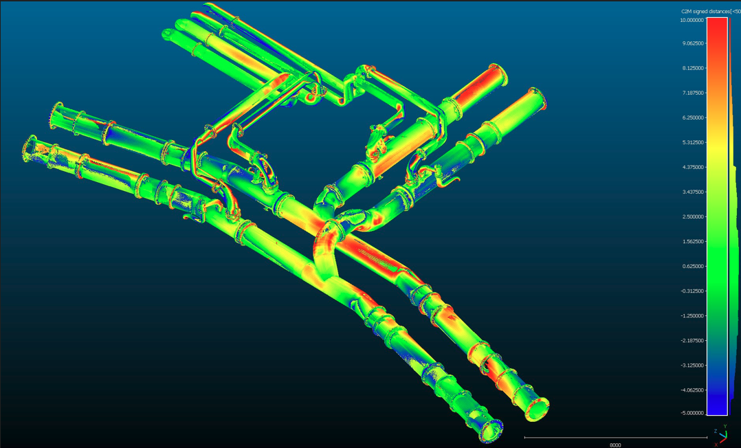

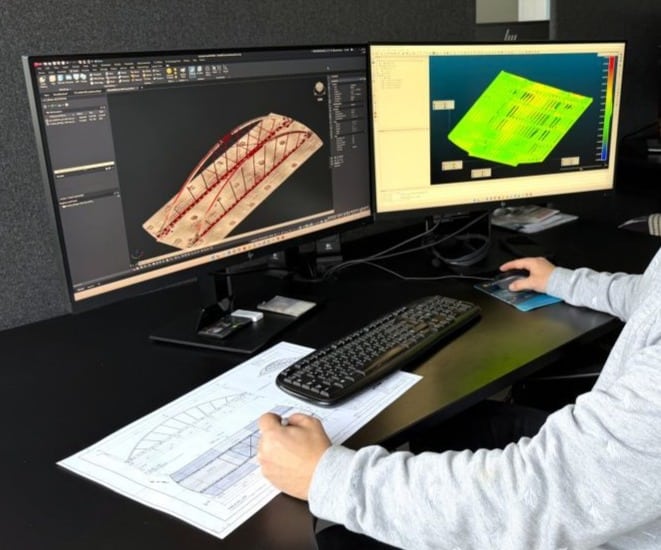

Factory Acceptance Testing (FAT) with Advanced 3D Scanning Technology

As part of our Factory Acceptance Testing (FAT) process, we use advanced 3D laser scanning technology to verify that every fabricated welded assembly and custom-manufactured product precisely matches the original engineering design specifications.

A high-resolution 3D point cloud scan of an industrial piping manifold system or large stainless steel structure enables a detailed heat map deviation analysis, directly comparing the as-built fabrication against the original CAD model dimensions.

The color-coded heat map ranges from blue (negative deviation) to red (positive deviation), clearly visualizing dimensional accuracy and fabrication tolerances. This Cloud-to-Mesh (C2M) comparison allows our engineers to identify even the smallest geometric deviations, ensuring full compliance before the product leaves our workshop.

At Western Technological Solutions, we bridge the gap between complex engineering design and high-precision metal fabrication through data-driven quality control, delivering reliable, inspection-ready products that meet the highest industrial standards.

Pickling & Passivation chamber for Stainless Steel

- Method: Spray pickling

- Working area: 200 m²

- Length: 20 m

- Width: 10 m

- Height: 10 m

- Gate Size: 7 × 8 m (W x H)

Western Technological Solutions operates a specialized, high-capacity pickling and passivation chamber. This facility is engineered for the advanced surface treatment of stainless steel, ensuring maximum corrosion resistance and surface integrity for large-scale industrial assemblies.

Utilizing the professional spray pickling method, the chamber applies a controlled chemical solution to restore the protective properties of the metal.

This process is essential for:

- Removing Weld Oxides: Eliminating heat tint and scale caused by welding.

- Surface Decontamination: Removing embedded iron particles and pollutants.

- Restoring the Passive Layer: Preparing the surface for the formation of a protective chromium oxide film.

The chemical reaction within our chamber precisely targets the iron-rich surface layer while preserving the underlying chromium-nickel matrix. This process is vital for stainless steel structures used in aggressive environments, such as road bridges, Carbon Capture (CCS), offshore oil&gas, power, and chemical processing.

Our pickling and passivation processes are executed under rigorous quality control, ensuring 100% compliance with the following EN and ISO standards:

- EN ISO 16048: Passivation of corrosion-resistant stainless-steel components.

- EN ISO 15730: Chemical and electrochemical treatment – Guide to the passivation and cleaning of stainless steel.

- ISO 8501-1: Preparation of steel substrates before application of paints and related products (Surface cleanliness).

- EN 10088: Stainless steels – Part 1: List of stainless steels (standard reference for material chemical composition).

By utilizing a dedicated, enclosed treatment chamber, Western Technological Solutions provides:

- Uniform Protection: Consistent chemical application across complex geometries and large-scale welded structures.

- Environmental Safety: Full containment of chemical fumes and efficient neutralization of waste according to EU regulations.

- Enhanced Durability: Prevention of localized pitting and crevice corrosion, significantly extending the service life of the equipment.

Western Technological Solutions is an expert in delivering large-scale industrial stainless steel projects that meet the highest regulatory and technical standards for demanding industries.

Painting chamber

- Working area: 1007 m²

- Length: 53 m

- Width: 19 m

- Height: 12 m

- Gate Size: 18 × 10 m (W x H)

A dedicated industrial painting chamber is essential for ensuring controlled, repeatable, and standards-compliant coating processes. This is especially true for large welded assemblies – such as those used in Carbon Capture and Storage (CCS) – where stainless steel and carbon steel are combined.

These controlled environments are critical for achieving high-performance protective coatings that withstand demanding industrial conditions.

One of the most common applications for combined stainless steel and carbon steel is the fabrication of rectangular self-supported towers. These structures typically feature:

- Internal Stainless Steel Sheeting: Interfaces with aggressive working media.

- External Carbon Steel Stiffeners: Vertical stiffeners and horizontal trusses welded to the stainless panels for structural integrity.

In these configurations, painting is often required for the external carbon steel side only. This mixed-material setup presents unique coating challenges that require a strictly controlled industrial painting environment to prevent cross-contamination and ensure long-term durability.

Performing industrial coating operations within a specialized chamber prevents contamination from dust, moisture, and airborne particles. Without these controls, coating adhesion and film thickness are compromised, leading to premature corrosion and expensive rework.

Our advanced industrial painting chambers provide:

- Uniform Airflow: Stable pressure control for consistent application.

- Climate Regulation: Precise temperature and humidity monitoring.

- Overspray Capture: Multi-stage filtration systems for a clean workspace.

- Enhanced Safety: Secure containment of coatings, solvents, and fumes.

Utilizing an industrial painting chamber ensures your projects meet rigorous European and international benchmarks, including:

- EN ISO 12944: Corrosion protection of steel structures by protective paint systems.

- EN ISO 2808: Determination of paint film thickness.

- EN ISO 8501 / 8502 / 8503: Surface preparation standards prior to painting.

Compliance is mandatory in high-stakes sectors like carbon capture, renewable energy, marine, offshore, oil&gas, power and heavy infrastructure.

Implementing a dedicated painting process delivers measurable benefits:

- Repeatable Quality: Consistent results across large-scale production runs.

- Cost Reduction: Minimized defects, rework, and coating failures.

- Worker Protection: Controlled exposure to hazardous overspray and fumes.

- Environmental Responsibility: Efficient emission control via filtration.

Western Technological Solutions specializes in the manufacturing of large-scale rectangular self-supported towers. With extensive experience in integrating stainless steel sheeting with carbon steel supports, we deliver industrial projects that fully comply with international standards and specific customer requirements.

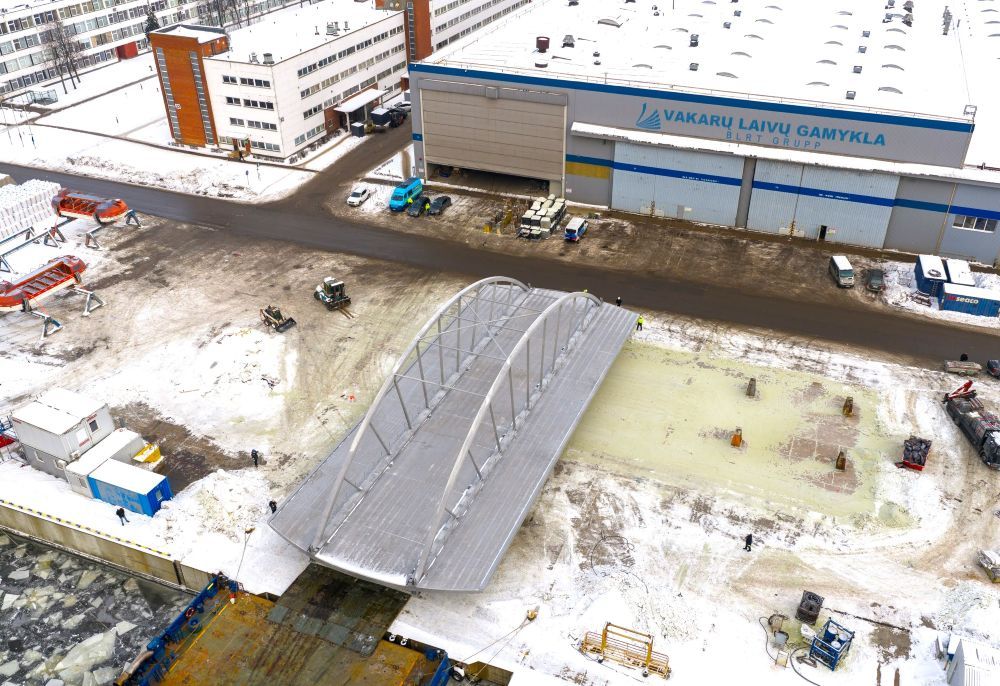

Assembly Areas

- Outdoor Assembly areas: 7000 m²

- Location: on the sea pier

- Easy access for 1,000-ton cranes and SPMT

- Typical dimensions of assembled one–piece structures: Up to 100х40×40 m (LxWxH)

- Climate Control: by a Temporary tent for welding operations

Western Technological Solutions operates large-scale outdoor assembly areas covering 7,000 m², strategically located on a sea pier to support heavy industrial and offshore projects.

These assembly areas are designed for mechanical assembly and welding of prefabricated modules into large, heavy, one-piece structures with significant dimensions, ensuring efficient preparation for loading and sea transportation.

The sea-pier location provides direct access to cranes with lifting capacities of up to 1,000 tons, as well as SPMTs (Self-Propelled Modular Transporters), allowing safe handling, positioning, and assembly of oversized and heavy structures.

Welding and assembly activities are carried out under temporary climate-controlled shelters, ensuring consistent weld quality, dimensional accuracy, and full compliance with international industrial welding standards, regardless of weather conditions.

Our outdoor assembly areas are optimized for complex heavy-lift and offshore fabrication projects, delivering precision, reliability, and seamless integration with marine logistics and load-out operations.

Contact us today to learn how our large-scale outdoor assembly and sea-pier load-out facilities support complex heavy-lift projects!

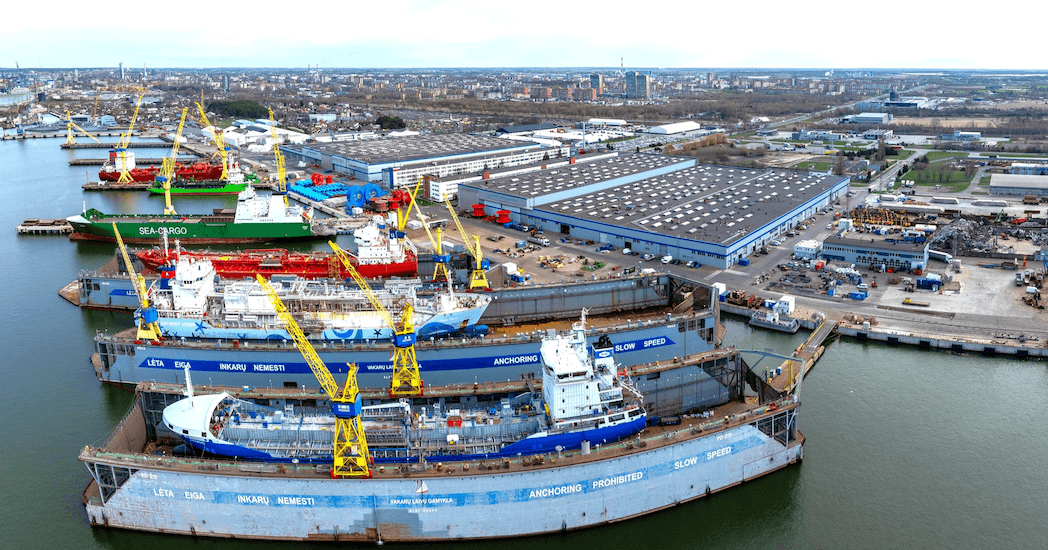

Sea pier

- Quay water depth: 14.5 m

- Quay length: 3 km

- Load-bearing capacity suitable for mobile crane operations and assembly of single-piece structures: up to 1,000 t

- Permanent Floating crane lifting capacity: 100 t

- Permanent Mobile crane (Liebher LHM 400) lifting capacity: 104 t

- Ten Permanent pier cranes (KONE/CERUTTI) lifting capacity: 30 t each

At Western Technological Solutions (WTS), we redefine the limits of industrial manufacturing. Being a key part of the Western Shipyard Group, our facility is strategically located directly on the Baltic Sea coast in Klaipeda, Lithuania. With only 70 meters separating our specialized stainless steel workshop from the deep-water sea pier, we eliminate the logistical "bottlenecks" that often plague large-scale engineering projects.

Our infrastructure is designed to handle the world’s most demanding industrial challenges. The facility available to Western Technological Solutions provides a seamless transition from fabrication to global shipping:

- Deep-Water Accessibility: With a quay depth of 14.5 meters, we can accommodate large-capacity vessels and heavy-lift carriers, ensuring your equipment reaches any international destination.

- Extensive Berthing Space: A 3 km long quay allows for simultaneous handling of multiple projects, ensuring flexibility and adherence to tight schedules.

- Heavy Lifting Power: Our logistical operations are supported by a formidable fleet of cranes and SPMT

Key Advantages for WTS Customers

- Unlimited Scale: Most manufacturers are limited by road transport dimensions. WTS can build massive, single-piece structures (tanks, scrubbers, and pressure vessels) that are loaded directly onto ships. If it fits on a vessel, we can build it.

- Reduced Project Costs & Risks: By eliminating inland transportation of oversized loads, we significantly reduce your logistics costs, permit fees, and the risk of transit damage.

- True Turn-Key Solutions: From 3D design and fabrication in our 3,240 m² stainless steel workshop to final FAT testing and sea shipment – everything happens in one secure, controlled location.

- Speed to Market: Direct access to the pier means no waiting for transport windows or road closures. Once your product is finished, it is ready to sail.

Whether you are in the Heavy Infrastructure, Carbon Capture, Oil & Gas, or Hydrogen industry, the synergy between Western Technological Solutions' engineering expertise and our world-class port infrastructure provides a competitive edge that few in Europe can match.

Contact us today to discuss how our "Shore-to-Ship" capabilities can streamline your next project!

Logistics & Delivery

We provide comprehensive, end-to-end logistics solutions to ensure your ordered products arrive on time, safely, and in perfect condition:

- Route Optimization & Calculation – Smart planning for cost-effective and timely deliveries.

- Sea, Road, Railway Transport – Flexible shipping options via SEA DELIVERY for large-scale products, road transport, and railway logistics.

Sea freight is the most efficient and cost-effective solution for transporting oversized or heavy cargo across long distances. - Port Forwarding & Handling – Seamless coordination for efficient port operations and cargo transfers.

- Customs Clearance Services – Expert management of all customs formalities to avoid delays.

- Professional Packing & Secure Packaging – Industry-standard solutions to protect your goods during transit.

We deliver fast, reliable, and cost-efficient logistics solutions, including sea freight for large-scale cargo, road transport, and railway logistics – ensuring every delivery meets your project requirements with precision and care.

Mechanical Installation & Industrial Thermal Insulation

Our capabilities extend to on-site mechanical installation for large-scale stainless steel projects, including industrial towers, tanks, and complex piping assemblies. Our expert teams ensure your project is completed on time and built to exact engineering specifications, ensuring seamless synchronization between construction phases and a flawless transition to full operational capacity.

In addition to standard installation, we offer professional Industrial thermal insulation application to enhance performance and energy efficiency of your industrial systems.

We work with a variety of high-performance materials tailored to the specific temperature and environmental requirements of your project:

- Stone Wool & Glass Wool: Ideal for high-temperature applications and fire safety, ensuring maximum thermal resistance and acoustic insulation.

- Polyurethane (PUR) Foam: Excellent for low-temperature processes and moisture resistance, providing a seamless, high-efficiency thermal barrier.

Single-Hand Solutions: From Fabrication to Site

Choosing a turn-key (hand-on-key) industrial partner for large-scale products offers significant strategic advantages:

- Single Point of Accountability: By managing everything from fabrication to final installation, we eliminate the "blame game" between different contractors. You have one partner responsible for the entire lifecycle.

- Cost & Time Efficiency: Turn-key delivery streamlines logistics and project management, significantly reducing the overhead costs associated with coordinating multiple vendors.

- Seamless EPC Integration: Our solutions are purpose-built to support complex Engineering, Procurement, and Construction (EPC) projects across Europe, ensuring that technical specifications are met from the workshop to the field.

- Guaranteed Quality Control: When we fabricate and install, we ensure that every weld and insulation jacket meets our rigorous internal standards and your specific project requirements.

- Reduced Operational Risk: Our experienced project teams handle advanced logistics and on-site safety, ensuring a precise, "hand-on-key" delivery that is ready for immediate operation.

Our installation processes meet the highest international quality standards while adhering to strict safety requirements. We focus on precision to ensure your new assets deliver long-term performance and high ROI. With advanced logistics and a commitment to excellence, we provide safe and efficient installation across Europe, regardless of project complexity.

Contact us today to discuss your next large-scale industrial project!