Western Technological Solutions is proudly certified by multiple accredited institutions, guaranteeing the highest standards of safety for our employees, exceptional quality in our stainless steel and aluminum products, and strong trust from our customers.

Compliance is at the core of everything we do.

PED – CE Marking

The Pressure Equipment Directive (PED) 2014/68/EU sets strict safety and quality standards for pressure vessels and related equipment across the European Union. At Western Technological Solutions, we meet all PED requirements with precision, ensuring every stainless steel pressure vessel we manufacture is fully compliant with EU regulations and delivers reliable performance.

ISO 3834-2: Certified Welding Excellence for Large-Scale Stainless Steel Structures

At Western Technological Solutions, welding quality is the foundation of our success. Our ISO 3834-2 certification confirms compliance with the highest international standards for welding processes, personnel competence, and quality assurance. This certification is essential for manufacturing large-format stainless steel components, including complex structures such as duplex steel bridges, pressure vessels, and heavy-duty industrial welding assemblies. ISO 3834-2 ensures:

- Superior Welding Quality – Every joint meets strict durability and safety requirements.

- Process Control – Comprehensive oversight of welding procedures and materials.

- Reliability at Scale – Expertise in delivering large, complex stainless steel structures with precision.

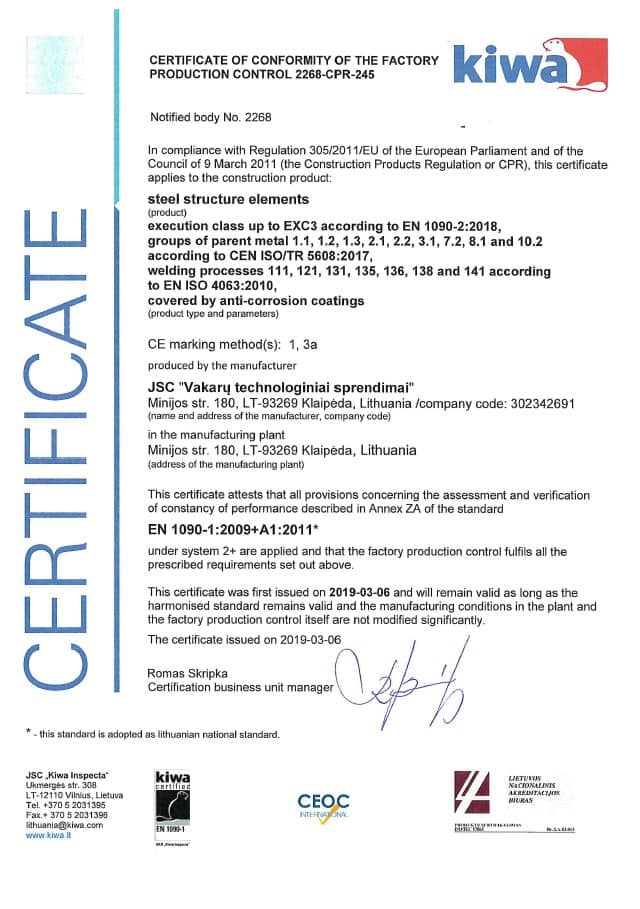

Certified Structural Excellence: EN 1090-2 EXC3 & EN 1090-3 EXC3

Understanding the EN 1090 Standard

In structural engineering and fabrication, EN 1090 is the cornerstone of quality and safety across Europe. This suite of European standards specifies the essential technical requirements for the execution (fabrication and erection) of structural steel and aluminum components. Every structural steel and aluminum component sold or used in the European Union must comply with this standard and carry the CE Marking. This ensures that the structure is fit for its intended purpose, guaranteeing a minimum, essential level of safety and reliability for all users.

The EN 1090 standard is divided into several parts:

- EN 1090-1: Requirements for conformity assessment of structural components

- EN 1090-2: Technical requirements for steel structures

- EN 1090-3: Technical requirements for aluminum structures

The Criticality of Execution Class 3 (EXC3)

The EN 1090 standard defines four Execution Classes (EXC1 to EXC4), which determine the required level of quality management, inspection, welding procedures, and personnel qualifications. This class is assigned based on the risk and potential consequences of structural failure.

Execution Class 3 (EXC3) represents a commitment to the highest levels of safety and quality control. It is reserved for structures where failure would lead to serious consequences for human life, significant economic loss, or considerable social or environmental impact.

EXC3 certification is typically required for critical applications such as:

- Bridges and large-span structures (e.g., footbridges, large roof structures)

- Buildings where failure would be catastrophic (e.g., highly populated or critical infrastructure)

- High-risk, dynamic-load structures (e.g., crane supports, structures subject to fatigue)

- Structures supporting heavy machinery or vital, non-redundant infrastructure

Our Dual Certification: EXC3 in Stainless Steel & Aluminum

Western Technological Solutions holds Execution Class 3 (EXC3) certification for both critical material groups: Stainless Steel (EN 1090-2) and Aluminum (EN 1090-3).

EN 1090-2 EXC3: Certified Stainless Steel Excellence

We are certified to deliver structural components in steel and stainless steel, including complex high-grade and duplex steels, under the most rigorous execution class.

Our EXC3 certification ensures we can handle the manufacture of:

- Large-format stainless steel components

- Complex projects such as duplex steel bridges and highly demanding industrial applications

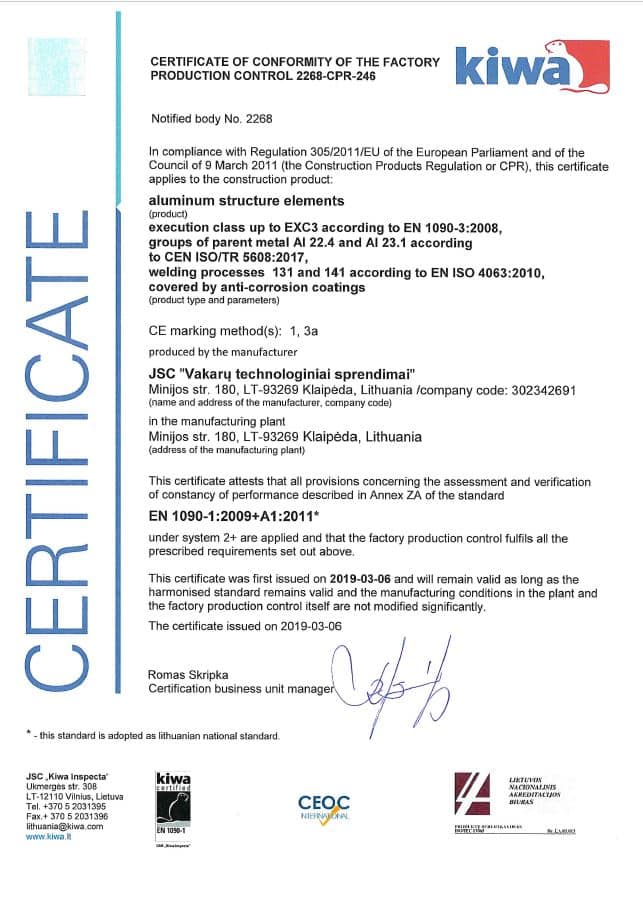

EN 1090-3 EXC3: Certified Aluminum Excellence

Our certification under EN 1090-3 EXC3 demonstrates our validated capability in fabricating complex aluminum structures.

This includes meeting the most demanding technical requirements for:

- Welding Quality: Strict adherence to ISO 3834-2, using qualified welders and approved Welding Procedure Specifications (WPS)

- Fabrication Control: Documented procedures for material traceability, cutting, forming, and assembly

- Personnel Qualifications: Certified welding coordinators and Non-Destructive Testing (NDT) personnel

- Inspection & Testing: Rigorous in-process and final inspections, including ultrasonic, radiographic, or penetrant testing to ensure zero defects in all critical joints

The Western Technological Solutions Advantage

Choosing Western Technological Solutions for your high-specification structural project delivers complete assurance:

- Guaranteed Compliance: Full adherence to European structural regulations with CE Marking qualification

- Maximum Safety: The highest level of quality control and inspection to mitigate structural risk

- Complex Project Capability: Proven expertise in demanding stainless steel and aluminum fabrications

- Full Traceability: Complete documentation of materials, welds, and processes throughout the project lifecycle

Partner with us to ensure your critical stainless steel and aluminum structures are built to the highest globally recognized EN 1090 EXC3 standard of certified excellence.

ISO 9001: Quality You Can Trust in Large-Scale Stainless Steel Manufacturing

At Western Technological Solutions, quality isn’t just a promise—it’s a system. Our ISO 9001 certification demonstrates a commitment to excellence in every stage of large-scale stainless steel production. This globally recognized standard ensures that our processes are efficient, consistent, and fully aligned with international best practices.

Why It Matters for You

- Consistent Quality at Scale – Whether you need a single custom stainless steel component or dozens, ISO 9001 guarantees uniformity and precision.

- Risk Reduction – Robust quality controls minimize defects and delays, protecting your timelines and budgets.

- Customer Confidence – Certification means your projects are backed by proven standards, ensuring reliability and trust.

Our Advantage

With ISO 9001, we combine advanced manufacturing capabilities with a structured quality management system, delivering stainless steel solutions that meet the highest industry requirements—on time and at scale.

Magnet JQS: Trusted Partner for Nordic Oil & Gas Projects

Western Technological Solutions is proud to be registered with Magnet JQS, the leading qualification system for suppliers in the Nordic oil and gas industry. This certification positions us as a trusted partner for major projects across Norway and the wider Nordic region, where compliance, safety, and reliability are critical.

Our Magnet JQS status confirms our ability to deliver large-format stainless steel components, pressure vessels, tanks, and sophisticated welded assemblies for demanding offshore and onshore applications, including complex structural solutions.

- Confidence in Compliance – Approved supplier for Nordic energy projects.

- Proven Expertise – Advanced capabilities in stainless steel fabrication at scale.

- Reduced Risk – Every product meets stringent industry standards for safety and performance.

By choosing Western Technological Solutions, you partner with a team committed to quality, compliance, and structural performance for the most challenging projects.