Western Technological Solutions delivers advanced stainless steel and aluminum equipment that directly supports Europe’s transition toward a net-zero future, lower emissions, cleaner air, cleaner water and environmentally responsible industrial operations. As part of the Western Shipyard Group and BLRT Grupp, the company manufactures large‑scale process equipment used across Hydrogen, Carbon Capture, Marine, Power, Chemical, Oil & Gas, Mining, Food, Water treatment, Wastewater treatment and Environmental industries.

We specialize in the fabrication of complex, large-scale stainless steel systems designed for air purification, carbon sequestration, and sustainable water management.

Our environmental product line is built on decades of engineering excellence, modern infrastructure at the Western Shipyard port pier in Klaipeda, and strict compliance with ISO and European manufacturing standards. We specialize in producing corrosion‑resistant, long‑lifetime large-scale equipment designed to minimize environmental impact throughout its full operational cycle.

Our Key Environmental Products and Systems:

We design and manufacture high‑efficiency scrubbers used to reduce harmful emissions in marine, energy, and industrial sectors. Flue Gas Desulfurization (FGD) systems play a critical role in removing sulfur oxides (SOₓ), particulates, and aggressive process gases, enabling cleaner exhaust streams and regulatory compliance.

Industrial scrubbers are designed to “wash” exhaust gases. As hot gases pass through the system, they are sprayed with a chemical slurry to neutralize pollutants like sulfur dioxide SO2. This process creates a highly acidic environment and involves abrasive particles. By utilizing Duplex and high-alloy stainless steels, we ensure maximum resistance against sulfuric acid corrosion.

- CO₂ Capture and Absorption Equipment

Carbon capture involves separating CO2 from industrial emissions before it reaches the atmosphere. The process often uses amines or other chemical solvents that become corrosive when heated during the “stripping” phase, where CO2 is separated for storage.

Our portfolio includes stainless steel absorbers, quenchers, and related CO₂ capture components used in large-scale decarbonization projects across Europe. These systems support industrial clients in reducing carbon emissions and meeting EU climate goals. Western Technological Solutions specializes in engineering and manufacturing stainless steel equipment for carbon capture and environmental applications.

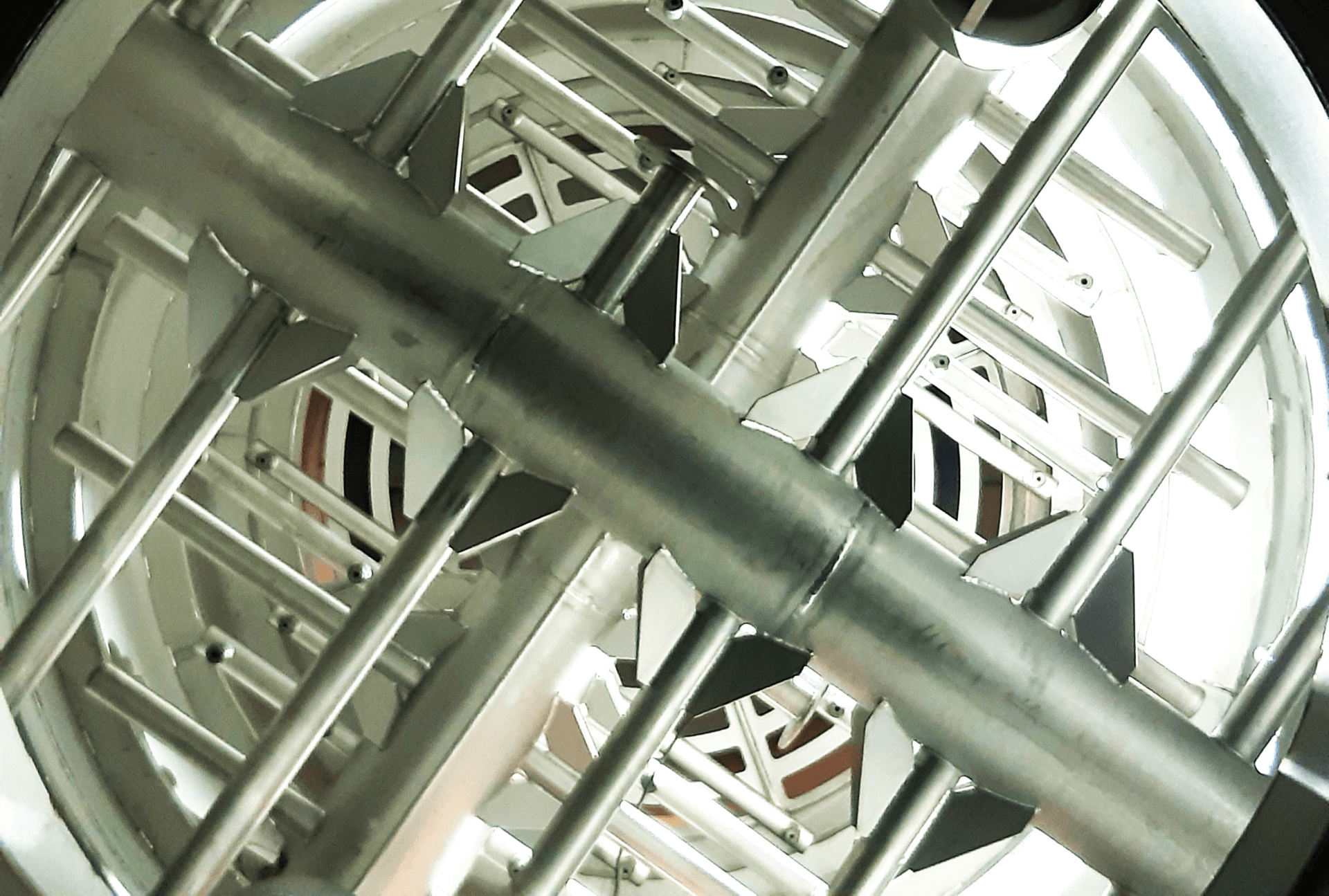

- Electrostatic Precipitators (ESP)

Electrostatic precipitators provide extremely efficient removal of solid particles from flue gases. These units are widely used in chemical, power generation, and process industries.

We manufacture heavy-duty ESP casings and internal components that capture fine dust and pollutants from industrial exhaust, ensuring compliance with EU air quality directives.

These systems use high-voltage electrostatic charges to remove fine dust and smoke particles from exhaust gases.

These units are often the first line of defense after a furnace, meaning they must handle flue gases at temperatures exceeding 300°C to 400°C.

Thermal-stable steel frameworks prevent the internal electrodes from warping, which would otherwise short-circuit the filtration process.

Western Technological Solutions provides ESP units as part of its comprehensive environmental engineering portfolio.

- Demisters

Demisters, also known as mist eliminators, are essential gas‑purification components used to remove fine liquid droplets from gas and vapor streams. These separation devices play a critical role in ensuring clean gas output and preventing liquid carryover that can damage downstream equipment.

Commonly integrated into scrubbers, absorbers, evaporators, and pressure vessels, demisters use woven mesh pads, vane packs, or structured stainless‑steel elements to capture aerosols as small as a few microns. This high‑efficiency droplet removal significantly enhances process performance while protecting compressors, turbines, heat exchangers, and other sensitive machinery from contamination and fouling.

Constructed from corrosion‑resistant stainless steel, demisters offer long service life and reliable operation in demanding environments such as chemical processing plants, marine applications, and wastewater treatment facilities. Their robust design ensures optimal gas–liquid separation, reduced maintenance, and improved overall system efficiency.

- Ducting and Gas Handling Systems

We manufacture corrosion‑resistant duct systems, piping systems, and large‑format gas‑handling assemblies required for air treatment lines in environmental plants. These systems ensure safe, reliable transportation of high‑temperature or chemically aggressive gases, supporting long‑term operational performance.

The operation of municipal and industrial water treatment and wastewater treatment facilities is impossible without corrosion‑resistant storage tanks, dosing tanks, filters, process vessels, pressure vessels, reactors, degassers, and welded piping assemblies. These systems must withstand high chloride concentrations, aggressive chemical environments, and strict safety requirements. Stainless steel—particularly duplex and austenitic grades—ensures long‑term reliability, structural integrity, and extended service life for critical water treatment processes.

- Tanks, Filters, Piping, Structures for Sustainable Aquaculture

The shift toward Recirculating Aquaculture Systems (RAS) demands materials that prioritize fish health and system longevity.

Our offerings for the aquaculture sector include:

- Biosecure Reservoirs & Tanks: Unlike plastic or concrete, our stainless steel tanks prevent biofilm buildup and bacterial colonization, ensuring a sterile environment for high-density fish farming.

- Filtration & Degassing Units: We manufacture complex mechanical filters and CO2 strippers that maintain water quality while minimizing environmental discharge.

- Durability in Harsh Environments: Our use of marine-grade alloys ensures that systems operating with saltwater remain corrosion-free for decades.

Sustainable Stainless Steel Engineering

Our environmental equipment is engineered primarily from austenitic and duplex stainless steels, which offer exceptional corrosion resistance, long service life, and natural material sustainability. Duplex stainless steels, in particular, support reduced lifecycle costs and environmental benefits, aligning with long‑term sustainability and operational efficiency goals. These materials deliver superior strength and corrosion resistance, making them ideal for modern environmental systems.

WTS offers more than just fabrication

we provide a strategic partnership for complex environmental projects:

- Large-Scale Capabilities: With the capacity to handle units up to 500 tons, pressure vessels and tanks 6 meters in diameter, we manage the projects others cannot.

- Port-Side Assembly: Located in the Western Shipyard port in Klaipeda, we offer direct sea-loading for oversized heavy environmental modules, reducing transport risks and costs.

- Certified Quality: Our welding and assembly processes meet the highest international standards (ISO, EN), ensuring the integrity of pressurized and hazardous-material systems.