Sustainable Bridges Made of Duplex Stainless Steel

Smart 120+ Year choice for Modern Infrastructure

In an era where infrastructure must withstand harsh environments while minimizing lifecycle costs, duplex stainless steel bridges are emerging as the smart choice for municipalities, architectural firms and contractors. Combining exceptional corrosion resistance and reliability, superior strength, and unmatched sustainability, duplex stainless steel (also known as austenitic-ferritic stainless steel) delivers bridges designed to last over 120 years with minimal maintenance.

Your Most Beneficial and Reliable Long-Term Solution

Traditional carbon steel bridges require frequent painting, repairs, and road closures due to corrosion from de-icing salts, marine air, or industrial pollution. In contrast, duplex stainless steel bridges eliminate these issues, reducing total lifecycle costs (LCC) and environmental impact. As a result, duplex bridges become the most cost-effective and beneficial solution for long service life.

Proven Duplex Stainless Steel Mastery in Landmark Projects

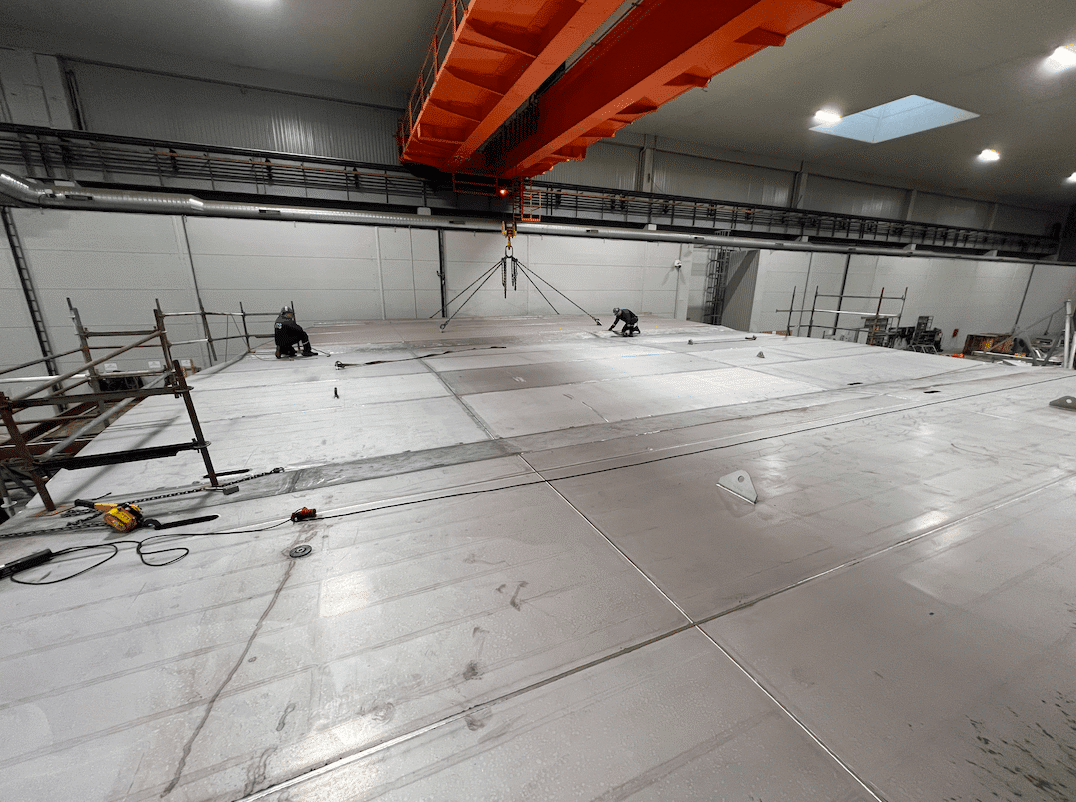

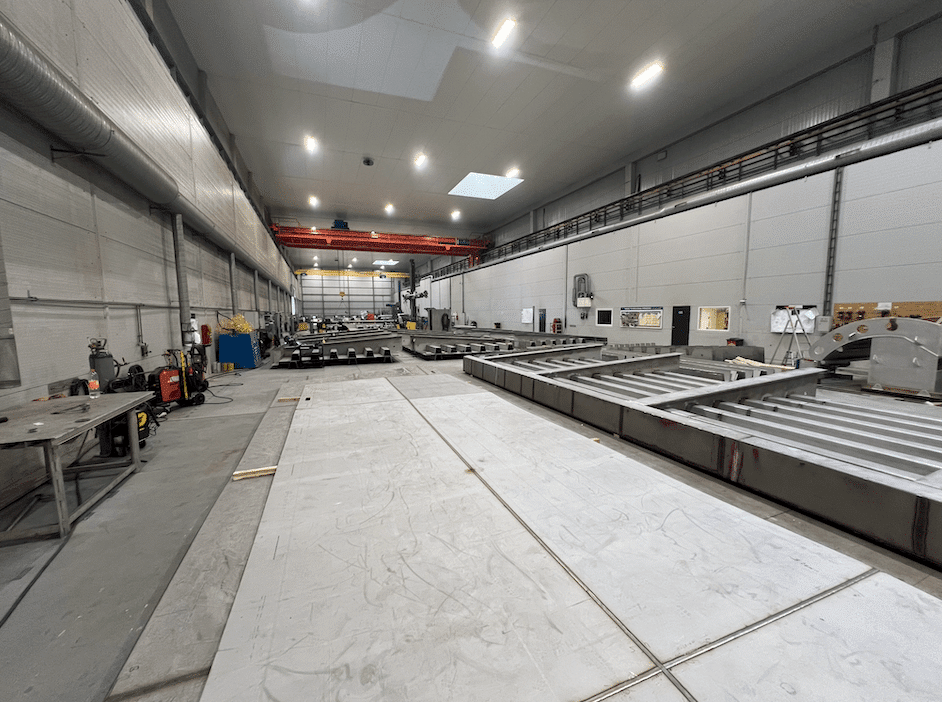

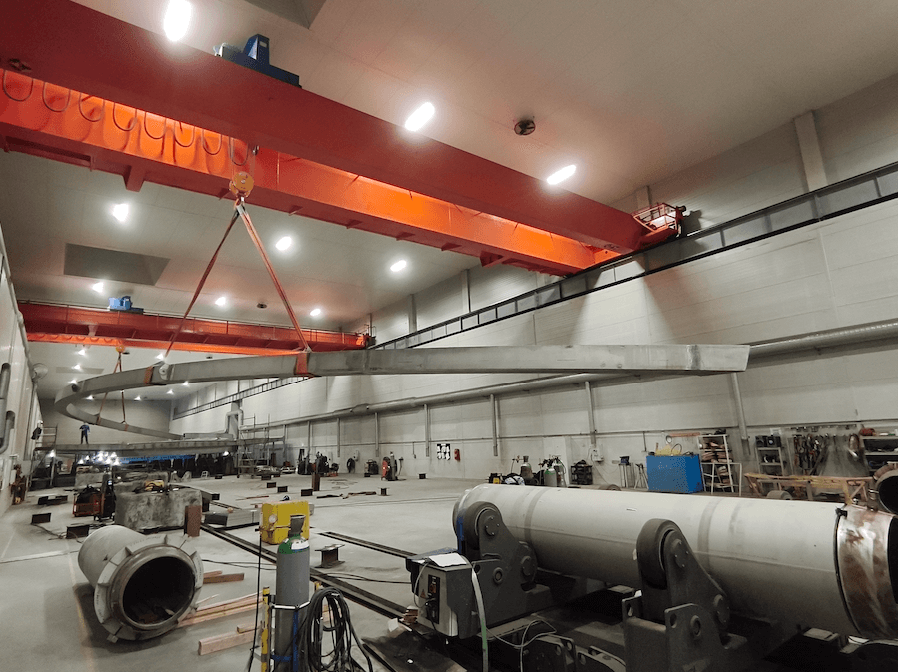

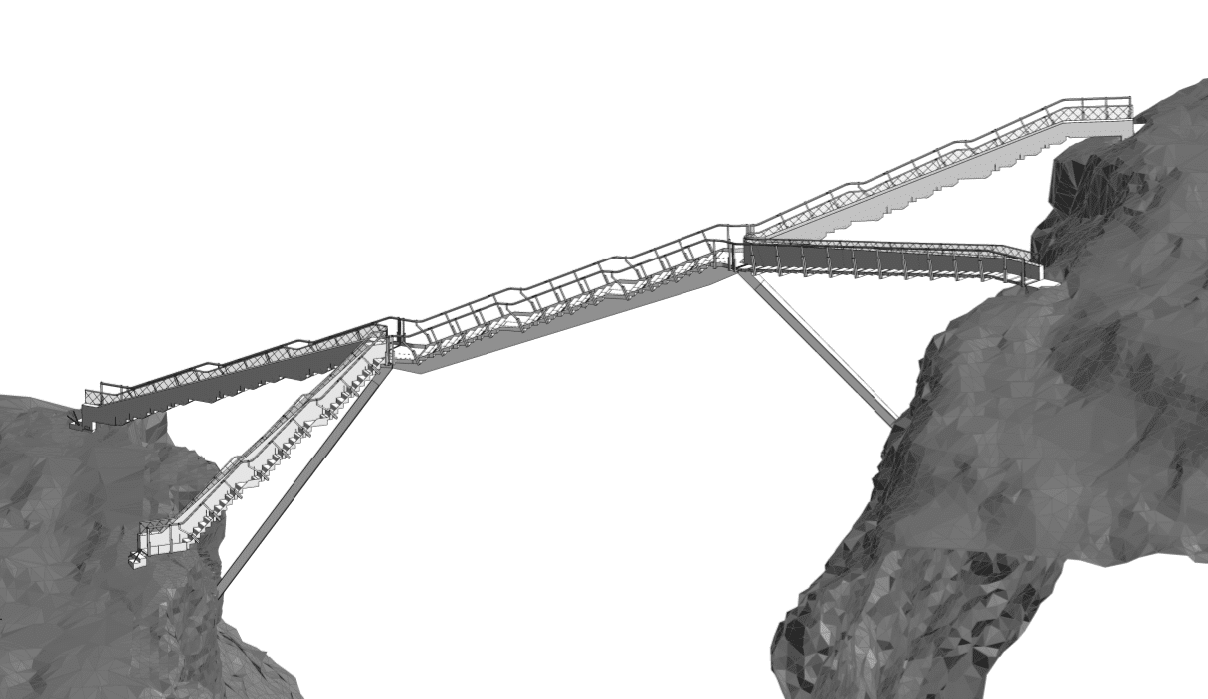

Our duplex stainless steel expertise shines through in two extraordinary projects: a breathtaking pedestrian bridge gracefully spanning an iconic Norwegian waterfall (2020), and a robust road bridge anchoring the heart of a major Swedish city, engineered to handle heavy traffic with the highest reliability and durability (2026). These achievements showcase our unmatched ability to combine cutting-edge duplex stainless steel technology with visionary design.

Showcasing Our Unique Duplex Stainless Steel Capabilities

Image by Helmut Seger, CC BY-SA 4.0, via Wikimedia Commons

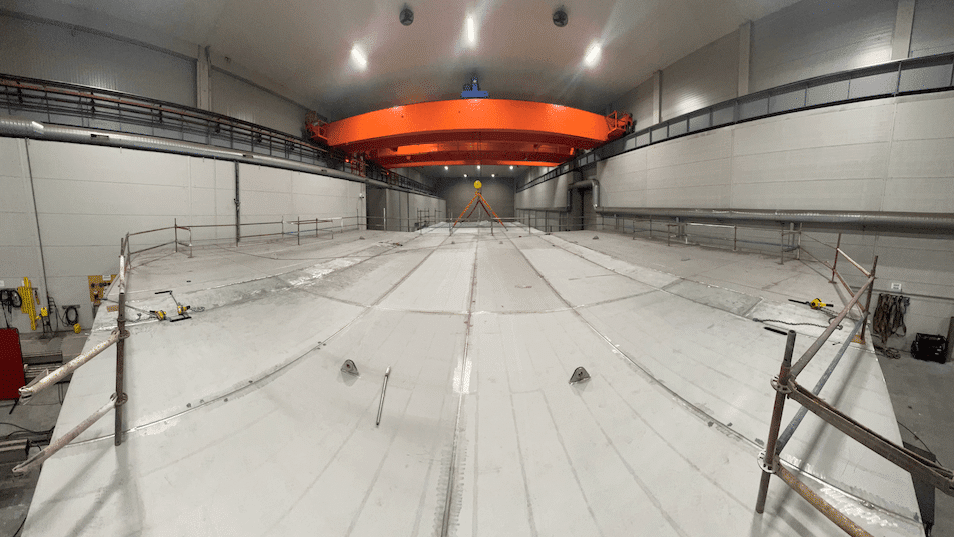

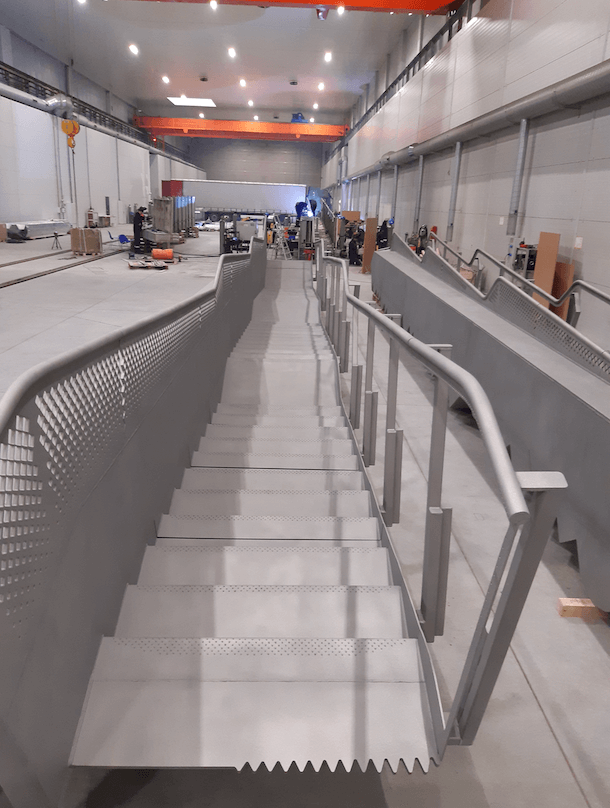

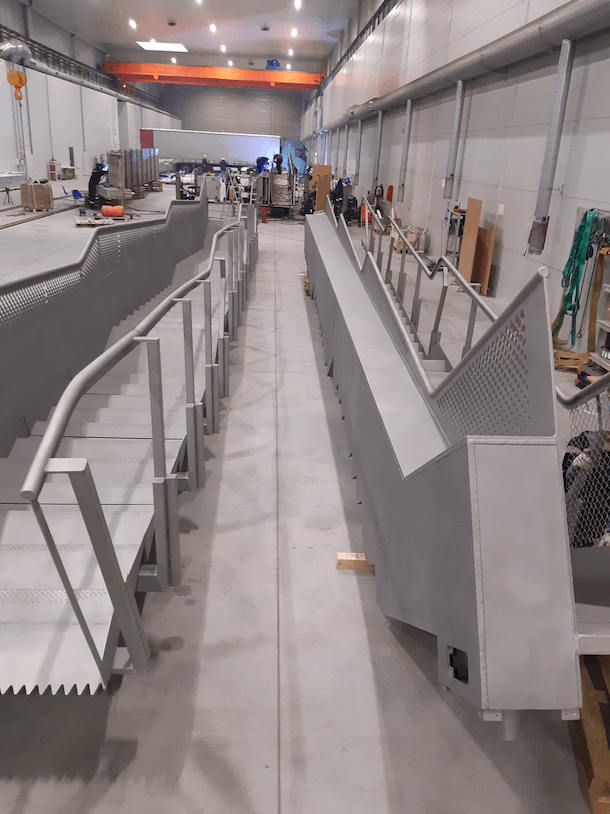

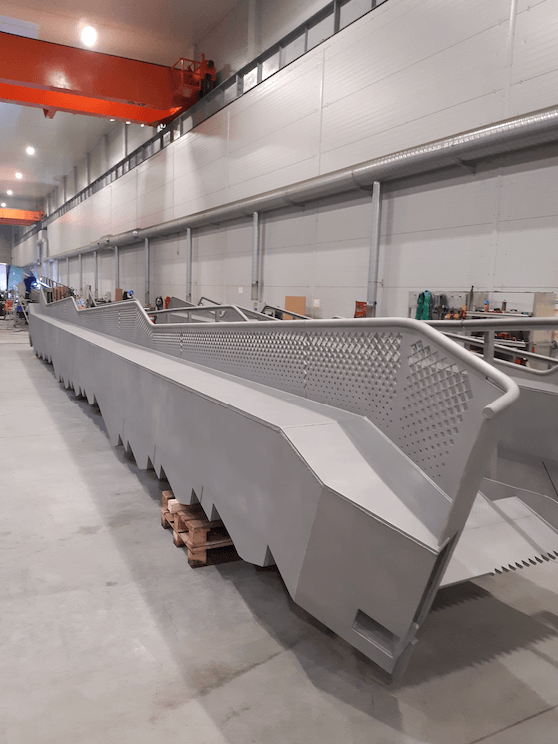

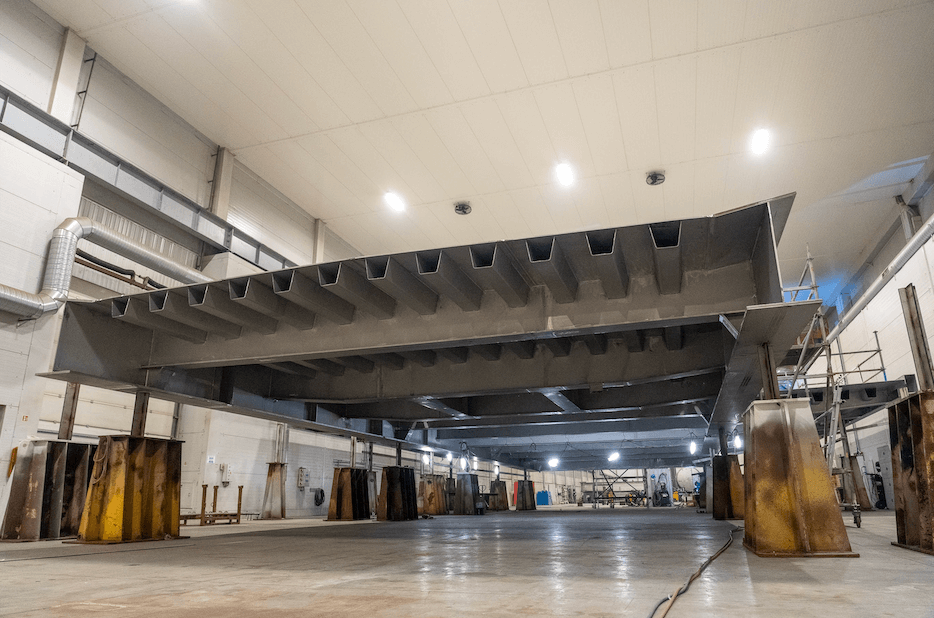

Building on our experience from the Norwegian project, our second project (2026) represents a major advancement: a state-of-the-art Duplex Stainless Steel road bridge in a major Swedish city center. This 45-meter span structure, weighing approximately 240 tonnes, is engineered to safely handle an average traffic volume of 16,000 vehicles per day.

The selection of Duplex stainless steel is strategic, providing exceptional durability for a bridge placed in a harsh, wet environment where it will be subjected to moisture and corrosive road salts. This material’s exceptionally high strength allows for a more efficient and lighter design, while its superior corrosion resistance guarantees a long service life with virtually zero maintenance costs associated with protective coatings, excluding traffic disruption for the city.

What Is Duplex Stainless Steel and Why Is It Ideal for Bridges?

Common grades for bridge construction include:

- EN 1.4162 (UNS S32101, LDX 2101) –This is a widely used lean duplex grade in bridge construction. Excellent strength-to-cost ratio.

- EN 1.4362 (UNS S32304, 2304) – Also commonly used lean duplex grade in European bridge projects where slightly lower corrosion resistance than EN 1.4462 is acceptable but still far superior to carbon steel.

- EN 1.4462 (UNS S32205/S31803, 2205) – Standard duplex with excellent pittingresistance. The “gold standard” duplex for bridges in aggressive environments (marine exposure, de-icing salts).

All of these grades form a stable passive chromium oxide layer that self-heals in the presence of oxygen, which is why duplex stainless steel bridges are routinely built without any paint or protective coatings

The principal properties of interest to bridge designers are:

- Strength: These duplex stainless steels have design strengths according to the Eurocode 3 (EN 1993-1-4) between 450 and 500 MPa, 30% to 40% stronger than the design strength of grade S355 carbon steel (355 MPa) that is generally used in bridges. Unlike carbon steel, no reduction in design strength for plate thickness exceeding 16 mm is required.

- High Ductility: Elongation 20–30%, ideal for seismic zones. Ductility is a measure of the capacity of a material to elongate under tensile loading before fracture occurs. Duplex stainless steels display high levels ductility (at least 25% for plates), which compare favourably with the relevant carbon steel grades.

- Toughness: All steel bridge components subject to tension must achieve a specified notch toughness in order to prevent brittle fracture. This depends on the minimum design temperature, stress level and material thickness. Duplex stainless steels display a more gradual ductile to brittle transition than carbon steels and retain their toughness down to around -40°С. (Minimum impact toughness values in the transverse direction at -40°С are 27 J for 1.4162 and 40 J for 1.4362 and 1.4462, which compare favourably to carbon steel.

- Excellent Weldability: Duplex stainless steels can be welded using a number of widely available processes; provided correct welding procedures are followed, this method of joining should be no more difficult than with carbon steel.

- Superior Fatigue Resistance: Matches or exceeds carbon steel.

- Durability: The high chromium content of duplex stainless steels, along with molybdenum and nickel, give them very good resistance to chloride-induced pitting and crevice corrosion. All duplex stainless steels grades show very good resistance to stress corrosion cracking (SCC). It is important that the chosen grade of duplex stainless steel is appropriate for the intended service environment since the price of the material generally increases with the corrosion resistance.

- Faster Construction: Lighter sections simplify transport and assembly.

Economic Advantages: Lower Total Lifecycle Costs for Duplex Stainless Steel Bridges

While initial material costs for duplex stainless steel are higher than carbon steel (e.g., S355), lifecycle cost analyses consistently show duplex bridges save money over 100–120 years.

Studies from Arup and independent LCC evaluations confirm lean duplex often has the lowest total cost for road, railway, and marine bridges.

Key Savings Areas:

| Benefit | Description | Impact on Costs |

|---|---|---|

| No Anti-Corrosion Coatings | Eliminates initial painting and repainting every 15–25 years (sandblasting + recoating) – 6–10 full repainting cycles. | Saves millions over 120 years; no toxic VOCs from paints. |

| Minimal Maintenance & Repairs | Intrinsic corrosion resistance prevents structural degradation from salts or pollution. | Reduces direct costs and avoids component replacements. |

| Reduced Indirect Costs | Fewer closures for bridges over railways, highways, or urban areas. | Less traffic disruption, lower user delay costs, reduced emissions from idling vehicles. |

| Lighter, Optimized Design | 25–50% higher yield strength than S355 carbon steel allows thinner sections and reduced weight. | Lowers transportation, erection, and foundation costs; ideal for pedestrian bridges with high surface-to-weight ratios. |

| Easier Graffiti Removal | Smooth stainless surface cleans effortlessly compared to weathering steel. | Additional long-term savings in urban settings. |

When planning a new bridge, the cheapest tender price is rarely the smartest choice. Stainless steel bridges — especially those made from duplex and lean-duplex grades — have a higher initial cost than traditional painted carbon steel or concrete structures, but they deliver dramatically lower total ownership costs over 100–150 years.

We at Western Technological Solutions encourage every client and consultant to perform a proper Life Cycle Cost Analysis (LCCA) before making a final decision. The numbers almost always show that our stainless steel bridges are the most economical solution in the long term.

Proven Benefits of Life Cycle Costing (LCC) in Infrastructure projects

- Enhanced Budget Planning: Accurate cost estimates prevent budget overruns.

- Sustainability: Encourages the use of eco-friendly materials and practices.

- Quality Assurance: Promotes the selection of durable, high-quality materials that reduce maintenance costs.

- Investment Efficiency: Ensures that capital is allocated to projects that offer the best long-term value.

By weaving LCC into every phase, organizations achieve harmony between fiscal discipline and planetary responsibility—resulting in resilient, future-proof infrastructure.

Mastering the Total Life Cycle Cost Formula

The cornerstone of effective analysis? A simple yet comprehensive equation that captures the full spectrum:

Total LCC = Initial Purchase Price + Operating Costs + Maintenance Costs + Replacement Costs – Residual Value

Essential Components Explained:

- Initial Purchase Price: Acquisition expenses, including bespoke design and fabrication—our Klaipeda expertise keeps these lean.

- Operating Costs: Ongoing expenses to operate the asset. Sustained operational outlays, optimized through efficient engineering.

- Maintenance Costs: Regular maintenance and repair expenses. Predictable repair budgets, minimized with corrosion-proof alloys.

- Replacement Costs: Costs for parts or systems that need to be replaced over time. Future swap-outs for wear-prone elements, anticipated via lifecycle modelling.

- Residual Value: The estimated value of the asset at the end of its life. Post-use worth through recycling, amplifying returns on sustainable steel and aluminum.

Life Cycle Cost Analysis (LCCA): A Complete Economic Roadmap

Life cycle cost analysis (LCCA) is a method of economic appraisal that evaluates all costs and benefits associated with a project over its entire lifespan. This comprehensive analysis helps stakeholders make informed decisions that consider both immediate and future financial implications. LCCA transcends basic budgeting—it’s a strategic appraisal of all expenses and gains over a project’s 50-100 year horizon.

Key Elements of Life Cycle Cost Analysis

- Initial Investment: The cost to start the project, including design and construction.

- Operating Costs: Ongoing expenses such as energy, labor, and materials.

- Maintenance Costs: Regular upkeep and repairs needed to keep the project functional.

- End-of-Life Costs: Costs related to decommissioning, disposal, or recycling.

- Benefits: Savings or revenue generated by the project over time.

Step-by-Step Guide: How to Perform LCCA for Your Bridge Project

- Define the analysis period – we recommend minimum 100 years (EN 1990 service life for major bridges).

- Choose realistic discount rate – usually 3–4 % in EU public projects.

- Include all cost elements – initial cost, periodic painting, inspections, repairs, traffic disruption, end-of-life removal/recycling.

- Use real maintenance data – Zero painting, only routine cleaning for existing duplex stainless steel bridges.

- Apply present value calculation (NPV) – Excel templates and ISO 15686-5 compliant tools are freely available.

- Compare at least three alternatives – painted carbon steel, weathering steel, and duplex stainless steel (our solution).

- Make the evidence-based decision – in 95 % of correctly performed analyses, stainless steel comes out as the clear winner. Let the mathematics — not the tender price — make the decision.

At Western Technological Solutions we do not ask you to trust marketing slogans.

We ask you to run an independent Life Cycle Cost Analysis (LCCA) yourself

Life-Cycle Cost Comparison

Duplex Stainless Steel Bridges vs Conventional Carbon Steel Bridges

(Based on 100-year design life, ISO 12944 and AASHTO guidelines)

| # | Parameter | Duplex Stainless Steel Bridges | Carbon Steel Bridges (painted) |

|---|---|---|---|

| 0 | Design life | 100–150+ years | 75–100 years (with aggressive maintenance) |

| 1 | Initial purchase price | €€ 2–3× higher than carbon steel |

€ |

| 2 | Operating costs | € Extremely low – no routine painting or corrosion monitoring |

€€€ Moderate to high – ongoing inspection and traffic management during painting |

| 3 | Maintenance costs | € (Minimal)

|

€€€€€ (Very high)

|

| 4 | Major rehabilitation / replacement costs | N/A Virtually none within 100 years |

€€€€€ (High) One or more full girder/deck replacements likely within 100 years in aggressive environments |

| 5 | Residual value after 100 years | ~100% of original steel weight (fully recyclable) | ~70–80% of initial weight (significant section loss due to corrosion) |

| 6 | 100-year NPV total Life-Cycle Cost (marine or heavy de-icing environments) |

€€€€ 0.8–1.4 × initial cost of painted carbon steel bridge (often lower) |

€€€€€€€€€ 2.0–4.0 × initial cost of painted carbon steel bridge (maintenance + rehabilitation dominate) |

| 7 | Risk & indirect costs | Extremely low risk of unexpected closure or failure | High risk of emergency repairs, traffic disruption, user delay costs (often >$100k/day) |

When you add all of that up and discount it to Net Present Value (NPV at 3–4 % real interest rate), the painted carbon-steel bridge ends up costing 3–6 times its original price over 100 years.

The duplex stainless bridge, after the initial construction, basically costs nothing for the next 100+ years.

That’s why, over a full century, the total life-cycle cost of the duplex bridge comes out to only 0.8–1.4 times the initial cost of a normal painted bridge — and in many cases it is actually the cheaper option.

This isn’t marketing hype. It’s plain math. Independent life-cycle cost analyses ( Trafikverket Sweden TRVINFRA-2022-066, UK National Highways “Use of Stainless Steel in Bridges” (2023), EU COST TU1406 Final Report (2024), Outokumpu & Acerinox 120-year LCC studies (2019–2024) using 3–4 % real discount rates show that duplex stainless steel bridges in coastal and de-iced environments have a 100-year Net Present Cost of 0.8 to 1.4 times the initial construction cost of equivalent painted carbon-steel bridges.

Bottom Line for Bridge Owners

In aggressive environments (coastal areas, de-iced highways), duplex stainless steel is simply the cheapest bridge money can buy — if you plan to own it longer than 20–30 years.

| Question | Duplex Stainless Steel | Painted Carbon Steel |

|---|---|---|

| Need to repaint the entire bridge every 20–30 years? | No | Yes (€€€€€ per cycle) |

| Risk of sudden closure for emergency repairs? | Almost zero | High |

| Total cost over 100 years | €€€€ | €€€€€€€€€ |

| Sustainability & Recyclability | 100 % of steel reused | Large amounts of paint waste & rust |

- Over a 100-year horizon, duplex stainless steel bridges are typically 30–60 % cheaper in total life-cycle cost than continuously painted carbon steel bridges in aggressive (C5/CX/Im4) environments.

- The higher initial material cost is offset within the first 20–40 years by eliminating painting cycles.

Environmental and Sustainability Benefits of Duplex Stainless Steel Bridges

Our expertise at Western Technological Solutions, backed by facilities at the Western Shipyard Group in Klaipeda, Lithuania, ensures that these bridges are prefabricated with precision, reducing on-site waste and emissions. As a key player in decarbonization, carbon capture and hydrogen industries, we apply the same sustainable practices to bridge engineering, ensuring our products contribute to a greener future.

Duplex stainless steel is one of the most sustainable structural materials:

1. Reduced Energy and CO2 Emissions

One of the primary environmental benefits of duplex stainless steel bridges is their lower embodied energy and CO2 footprint over the full lifecycle. While the unit weight embodied values for duplex stainless steel are higher than carbon steel, the duplex stainless steel material’s superior strength allows for lighter structures. This means less material is needed to achieve the same load-bearing capacity, resulting in up to 30% weight reduction compared to S355 carbon steel bridges.

In practice, this translates to fewer raw materials extracted and processed, cutting energy consumption during manufacturing. Transportation emissions are also minimized due to lighter shipments—especially beneficial for our sea-based logistics from the Baltic Sea. A comparative Life Cycle Assessment (LCA) highlights that sustainable duplex stainless steel bridges can outperform concrete or painted carbon steel options in CO2 savings, particularly in long-span designs where material efficiency is critical.

2. Avoiding Emissions and Pollution

The production of protective paints for carbon steel bridges releases significant harmful substances, including volatile organic compounds (VOCs), solvents, and heavy metals such as lead and chromium, which adversely affect air and water quality while posing health risks to manufacturing personnel through inhalation and skin exposure. During the application and re-application of these coating systems—both initial painting and periodic maintenance—additional VOC emissions occur, contributing to ozone formation, smog, and respiratory issues for repair crews and nearby communities. Studies show that bridge painting operations can expose workers to VOC levels exceeding safety thresholds, with emissions intensifying in confined or outdoor settings during summer months.

Furthermore, in harsh environments like coastal or de-iced road areas, painted carbon steel bridges undergo inevitable degradation, leading to the flaking of paint particles and rust. This results in ongoing environmental pollution through dust and particulate matter that contaminates soil, waterways, and air. Rust particles often contain iron oxides and residual heavy metals from coatings, which can leach into ecosystems, harming aquatic life and biodiversity. Paint removal during maintenance generates hazardous waste, including abrasive blast media laden with toxins, complicating disposal and increasing landfill burdens.

In contrast, duplex stainless steel bridges eliminate the need for protective coatings due to their inherent corrosion resistance, avoiding these emissions and pollutants entirely. This not only reduces the carbon footprint associated with paint production and application—estimated at up to 10-20 kg CO₂ per square meter of coated surface—but also prevents long-term environmental contamination, aligning with sustainable infrastructure goals at Western Technological Solutions.

By opting for duplex stainless steel designs, projects minimize health hazards, regulatory compliance costs, and ecological damage, fostering cleaner air, water, and safer work environments over the bridge’s 100+ year lifespan.

3. Reduced Traffic Emissions

Duplex stainless steel bridges, with their exceptional durability and corrosion resistance, require significantly less maintenance than traditional materials like painted carbon steel or concrete, resulting in fewer road closures and reduced traffic congestion. This minimizes CO₂ emissions from idling vehicles, detours, and increased travel times during repairs or inspections. For instance, lifecycle assessments indicate that traffic restrictions during bridge maintenance can account for 5-7% of total maintenance-related emissions in preventive strategies. In broader operation and maintenance phases, vehicle traffic emissions often dominate the environmental impact, contributing up to 64% in some bridge analyses. Traffic diversions alone can add substantial CO₂ from extra fuel consumption, as quantified in studies on infrastructure projects. By extending service life and avoiding frequent interventions, duplex stainless steel bridges promote smoother traffic flow, lowering overall carbon footprints and supporting sustainable urban mobility—key for high-traffic areas where our prefabricated solutions at Western Technological Solutions excel in minimizing on-site disruptions.

4. 100% Recyclability and Re-Use

Duplex stainless steel is fully recyclable without any loss of quality or performance, boasting end-of-life recycling rates of up to 100%—one of the highest among structural materials. This closed-loop system minimizes the demand for virgin resources, conserving non-renewable ores and energy while significantly reducing environmental impact. At the end of a bridge’s 100+ year lifespan, components can be easily dismantled, recycled, or re-used in new projects, avoiding landfill waste and aligning with circular economy principles.

In contrast, non-metallic alternatives like concrete often result in substantial demolition waste that is difficult to repurpose, and concrete production is one of the most CO2-intensive processes in construction, contributing around 8% of global emissions.

Recycling painted carbon steel structures poses additional challenges and is far less eco-friendly; during remelting, protective coatings combust, releasing harmful emissions such as volatile organic compounds (VOCs), dioxins, and particulate matter. These pollutants are complex and costly to capture from flue gases, increasing the overall environmental burden compared to unpainted, corrosion-resistant duplex stainless steel.

By choosing duplex stainless steel bridges, infrastructure projects achieve superior sustainability through effortless recyclability and reduced long-term emissions.

5. Lightweight Construction for Minimal Impact

The high strength-to-weight ratio of duplex stainless steel enables slimmer, lighter bridges that span greater distances without intermediate supports. This reduces the environmental footprint in several ways: fewer foundations mean less ground disturbance, excavation, and habitat disruption—ideal for sensitive areas like river estuaries or urban zones.

Larger spans also eliminate hazards for waterways, improving navigation safety and reducing pollution risks during construction. Overall, lightweight duplex stainless steel bridges lower CO2 emissions through reduced material use and transportation. For instance, in marine environments, our bridges withstand typhoons and salt exposure without coatings, avoiding the environmental burdens of paint application and maintenance.

6. Waste Minimization and Efficient Fabrication

Our computer-aided design and prefabrication processes optimize material usage, generating minimal waste that is fully recycled. This lean approach aligns with sustainable themes like avoiding pollution and conserving water resources. By manufacturing in controlled factory settings, we minimize on-site activities, cutting energy use and emissions from construction equipment.

By choosing our solutions, clients contribute to biodiversity preservation and resource conservation, key themes in sustainable construction.

Life Cycle Assessments (LCA) confirm duplex bridges have a smaller environmental footprint than painted carbon steel equivalents.

At Western Technological Solutions, we draw on these successes to deliver eco-friendly duplex stainless steel bridges for infrastructure clients. Our focus on industries like carbon capture and marine engineering ensures that sustainability is embedded in every project. Further research, including LCAs, continues to quantify advantages over conventional materials, but the evidence is clear: duplex stainless steel bridges offer superior corrosion resistance, reducing repair needs and extending service life.

In conclusion, the environmental and sustainability benefits of duplex stainless steel bridges make them a smart investment for future-proof infrastructure.

By partnering with Western Technological Solutions, you gain access to high-performance, low-impact solutions that support decarbonization goals.

Contact us today to explore how our sustainable bridge designs can enhance your next project, promoting a balance of durability, efficiency, and environmental stewardship.

TOP – 29 Duplex Stainless Steel Bridge Projects Worldwide

| No. | Year | Bridge Name | Country | Type | Duplex Grade (Original / EN 10088-3) |

Main Span / Total Length |

Key Highlights |

|---|---|---|---|---|---|---|---|

| 1 | 2026 | City center | Sweden | Road | Lean duplex / 1.4162 | 45m, 240t |

Entire duplex stainless steel welded arch bridge designed for heavy traffic in the major city center |

| 2 | 2025+ | Nya Årstabron (new Årsta rail bridge) |

Sweden | Railway (double-track) |

LDX 2101 + 2205 / 1.4162 + 1.4462 |

~300 m | Largest ongoing duplex rail project in Europe |

| 3 | 2025 | Hangarbrua Pedestrian Bridge | Norway (Trondheim) |

Pedestrian / cycle | 2205 tension rods / 1.4462 |

100 m | World’s first 100% recycled aluminum deck with duplex rods; 100-year maintenance-free |

| 4 | 2023 | Marina Bay Bridge extension | Singapore | Pedestrian/vehicular | 2205 / 1.4462 | – | Extension of Helix area |

| 5 | 2022 | Lusail Light Rail bridges | Qatar | Light rail | 2205 / 1.4462 | – | Extreme desert + marine climate |

| 6 | 2021 | Mongstad Refinery Footbridges (Sverdrup series) |

Norway (Mongstad) |

Pedestrian (industrial) | LDX 2101 / 1.4162 | 20–30 m each (2 bridges) |

Lean duplex replacement for carbon steel; sustainable, low-maintenance in refinery environment |

| 7 | 2021 | Apaté Bridge | France (Réunion Island) |

Road | Lean duplex / 1.4162 | 280 m | World’s highest lean-duplex road bridge |

| 8 | 2020 | Vøringsfossen Step Bridge | Norway (Hardangervidda) |

Pedestrian (step) | 1.4162 + 1.4401 | 47 m (99 steps) | Iconic staircase over Norway’s largest waterfall; duplex for wet, corrosive conditions |

| 9 | 2020 | Pooley Bridge | United Kingdom | Road (composite arch) | LDX 2101 / 1.4162 | 45 m | UK’s first all-stainless road bridge |

| 10 | 2020 | Athabasca River Bridge | Canada (Alberta) |

Road | 2205 / 1.4462 | 120 m | Extreme cold + de-icing salt resistance |

| 11 | 2019 | Garrison Crossing (Canoe + Fort York bridges) |

Canada (Toronto) |

Pedestrian / cycle | UR™ 2205 / 1.4462 | 50–60 m each | North America’s first fully duplex bridges (300 t) |

| 12 | 2018 | Söderström Railway Bridges (Stockholm) |

Sweden | Railway (4 parallel spans) | LDX 2404 / 1.4662 | 150–200 m each | World’s longest stainless railway complex (~600 t) |

| 13 | 2015 | Sickla Footbridge 2 | Sweden | Pedestrian | 2205 / 1.4462 | 32 m | Harsh Nordic climate |

| 14 | 2014 | Harbor Drive Pedestrian Bridge (official opening) |

USA (San Diego) | Pedestrian (self-anchored) |

Forta DX 2205 / 1.4462 | 168 m (550 ft) | Longest self-anchored stainless pedestrian bridge |

| 15 | 2013 | 7th Street Bridge | USA (Fort Worth, Texas) | Vehicular | 2205 / 1.4462 | 90 m | Early major vehicular duplex use in USA |

| 16 | 2012 | Likholefossen Footbridge | Norway | Pedestrian | 2205 / 1.4462 | 30 m | Lightweight design for cold climate |

| 17 | 2012 | Environmental Pedestrian Bridges (series) |

Sweden | Pedestrian modular | 2205 / 1.4462 | 25–50 m | Multiple urban installations |

| 18 | 2011 | Añorga Railway Bridge | Spain (San Sebastián) | Railway | LDX 2101 / 1.4162 | 60 m | First railway bridge chosen for lean duplex purely on cost |

| 19 | 2010 | The Helix Bridge | Singapore | Pedestrian (DNA helix) | 2205 / 1.4462 | 280 m | Iconic double-helix, 650 t duplex tubes |

| 20 | 2010 | Sant Fruitós Pedestrian Bridge | Spain (Barcelona area) |

Pedestrian / light vehicular | LDX 2101 / 1.4162 | 40 m | Hybrid tilted-arch with GFRP deck |

| 21 | 2009 | Stonecutters Bridge | Hong Kong, China | Cable-stayed road | 2205 (Code Plus Two) / 1.4462 |

1,018 m | ~1,600 t duplex cladding & anchorages |

| 22 | 2008 | Ruffolo – Siena Footbridge | Italy | Pedestrian (cable-stayed) |

LDX 2101 / 1.4162 | 60 m | World’s first major lean-duplex bridge |

| 23 | 2007 | Menorca Secondary Bridge | Spain (Menorca) | Vehicular | 2205 / 1.4462 | 36 m | Companion to Cala Galdana |

| 24 | 2006 | Simone de Beauvoir Bridge | France (Paris) | Pedestrian | 2205 elements / 1.4462 | 304 m total |

Curved design over the Seine |

| 25 | 2006 | Celtic Gateway Bridge | United Kingdom (Wales) | Pedestrian arch | 2205 / 1.4462 | 80 m | Early UK duplex application |

| 26 | 2005 | Cala Galdana Bridge | Spain (Menorca) | Vehicular arch | 2205 / 1.4462 | 55 m | World’s first vehicular duplex arch bridge |

| 27 | 2003 | Sicklauddsbron | Sweden | Pedestrian | 2205 / 1.4462 | 62 m | One of the first fully stainless pedestrian bridges in Europe |

| 28 | 2002 | Kungälv Railway Bridge | Sweden | Railway | 2205 / 1.4462 | – | First-ever railway application of duplex stainless |

| 29 | 2001 | Padre Arrupe Footbridge | Spain (Bilbao) | Pedestrian | 2205 / 1.4462 | 35 m | One of the very first duplex stainless steel bridges worldwide |

Projects that Western Technological Solutions has been involved in are highlighted in green.

Why Choose Duplex Stainless Steel for Your Next Bridge?

For coastal, urban, railway, or high-traffic projects, duplex stainless steel bridges deliver:

- Cheapest of the total life-cycle cost

- The highest reliability of communication routes throughout their entire service life of 120 years

- Maximum environmental friendliness

- Unrivalled durability in aggressive environments.

- Enhanced sustainability and aesthetics.

- Faster, safer construction.

Invest in infrastructure that lasts generations!

Contact duplex stainless steel specialists today to explore how this material can transform your bridge project.