Flue Gas Treatment

Innovative Solutions for a Sustainable Future

Reducing greenhouse gas emissions is a critical goal for modern industries, and Western Technological Solutions provides reliable answers with advanced Carbon capture, green Hydrogen, and environmental equipment. Our systems are engineered to meet strict environmental regulations while ensuring long-term efficiency and durability.

Expertise Beyond Carbon Capture

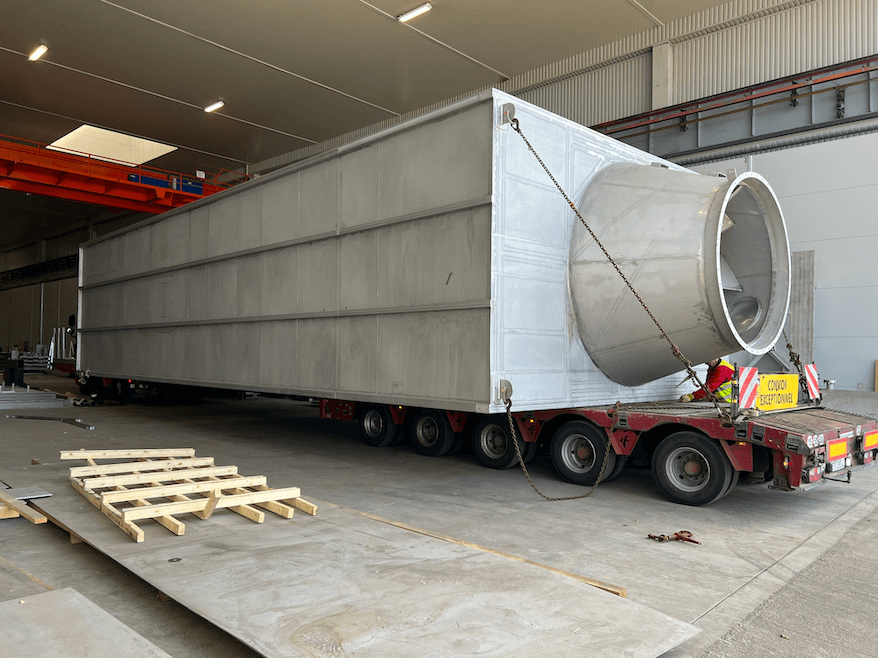

While our focus includes CO₂ capture and environmental equipment, Western Technological Solutions also manufactures pressure vessels, storage and fuel tanks, scrubbers (exhaust gas scrubbers), and custom welding assemblies in stainless steel and aluminum. This broad expertise allows us to deliver complete solutions that serve industries ranging from energy and shipping to chemical and food processing.

A Trusted Partner for Sustainable Growth

Each project we deliver is backed by strict quality standards, advanced engineering, and a commitment to environmental responsibility. Whether you require a CO₂ absorber, a precipitator, or a complete carbon capture system, we provide solutions that support both regulatory compliance and sustainable growth.

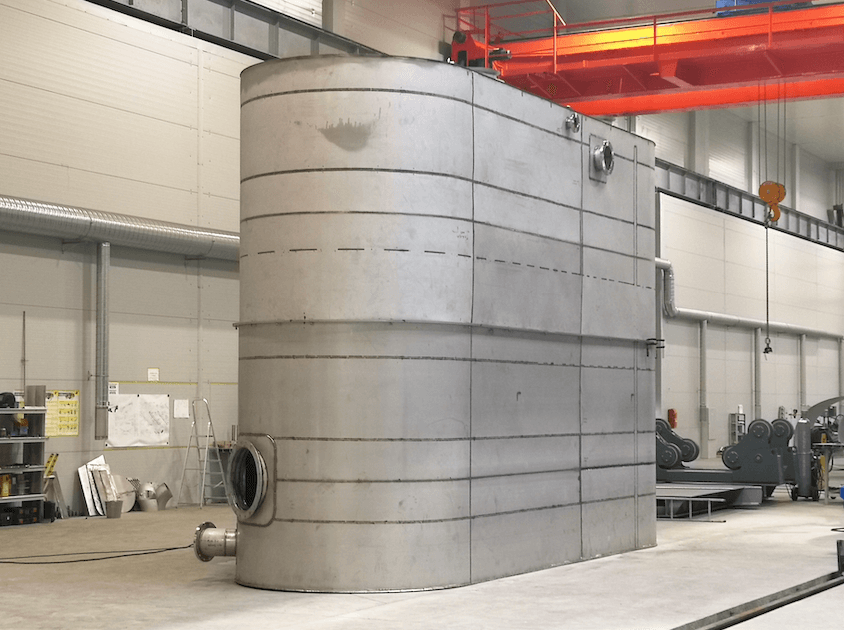

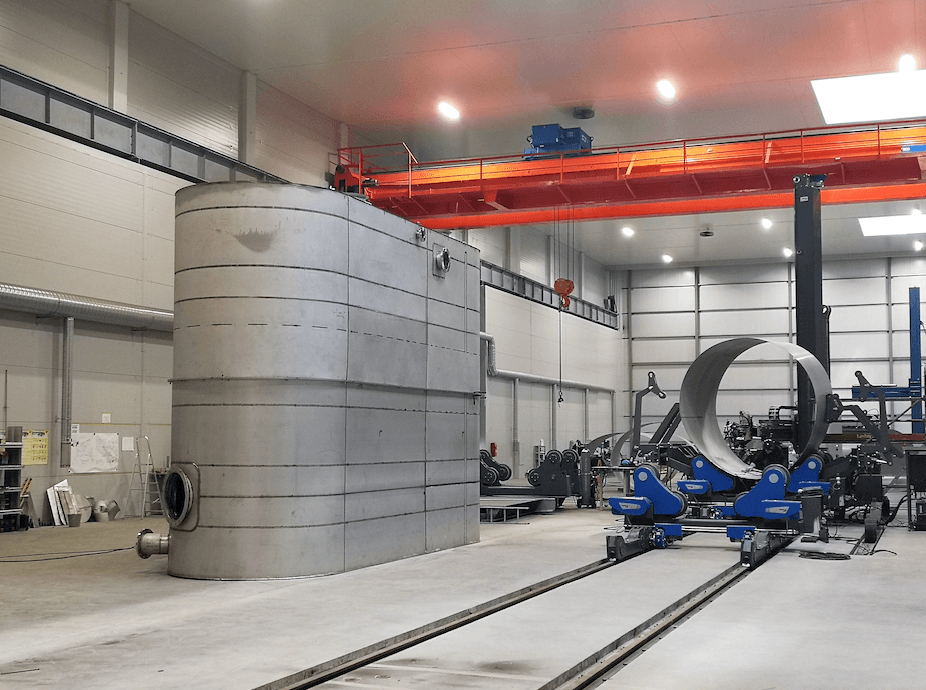

Among the key products in this field are CO₂ absorbers, designed to remove carbon dioxide effectively from flue gases in industrial and thermal energy applications. Our product line also includes high-efficiency electrostatic precipitators that capture fine particulate matter (PM) from flue gases, along with mist eliminators (demisters) and robust ducting systems that integrate seamlessly into broader process infrastructures. Together, these solutions form the backbone of effective carbon capture technology, ensuring that industries can reduce their environmental footprint without compromising productivity.

Technological Expertise

Advanced stainless steel and aluminum solutions for industrial precision.

Comprehensive Capabilities

Full-cycle production from engineering to delivery in one hands.

Experienced Team

Skilled professionals backed by Western Shipyard Group and

BLRT Group.

Quality Assurance

Certified to ISO 9001,

EN 1090 EXC3, and

ISO 3834-2 for proven excellence.

Client-Oriented Approach

We adapt to every client’s unique needs for optimal project results.

International Presence

Part of BLRT Group, serving clients across the Baltic and global markets.